C-Charts and U-Charts: Monitoring Defects in Variable-Sized Samples

Associated Articles: C-Charts and U-Charts: Monitoring Defects in Variable-Sized Samples

Introduction

With enthusiasm, let’s navigate by means of the intriguing subject associated to C-Charts and U-Charts: Monitoring Defects in Variable-Sized Samples. Let’s weave attention-grabbing info and provide recent views to the readers.

Desk of Content material

C-Charts and U-Charts: Monitoring Defects in Variable-Sized Samples

Management charts are basic instruments in Statistical Course of Management (SPC) used to watch course of stability and determine potential sources of variation. Whereas many are aware of X-bar and R charts for steady information, the C-chart and U-chart are particularly designed for analyzing depend information, notably the variety of defects or nonconformities present in a pattern. Crucially, in contrast to different management charts, these charts accommodate samples of various sizes. This makes them notably helpful in conditions the place the pattern dimension is not fixed, a standard incidence in lots of manufacturing and repair processes.

This text delves into the intricacies of C-charts and U-charts, exploring their purposes, development, interpretation, and limitations. We’ll look at the important thing variations between them and supply sensible examples for instance their utilization.

Understanding C-Charts

A C-chart is used to watch the variety of defects present in a constant-sized pattern. The "C" represents the depend of defects. This suggests that every unit inspected can have a number of defects. As an illustration, a C-chart might observe the variety of scratches on a batch of 100 painted automotive doorways, the variety of spelling errors in a 500-word doc, or the variety of blemishes on a batch of 200 apples. The important thing attribute is that the pattern dimension stays constant throughout all subgroups.

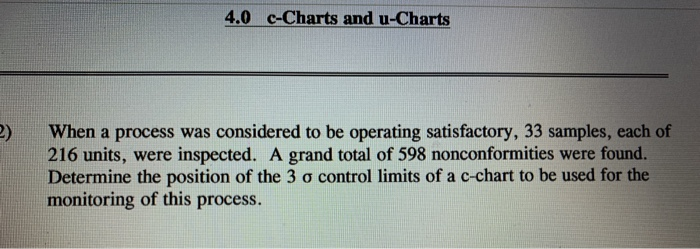

Development of a C-Chart:

-

Information Assortment: Collect information on the variety of defects (C) in every pattern of a constant dimension (n). Make sure the samples are unbiased and consultant of the method.

-

Calculate the Common Variety of Defects: Calculate the typical variety of defects (C-bar) throughout all samples. That is accomplished by summing the variety of defects in every pattern and dividing by the entire variety of samples.

C-bar = ΣCi / ok

the place:

- ΣCi = the sum of defects in all samples

- ok = the variety of samples

-

Calculate the Management Limits: The management limits are calculated utilizing the Poisson distribution, which is acceptable for depend information. The usual deviation of the variety of defects is the sq. root of the typical variety of defects (√C-bar).

- Higher Management Restrict (UCL) = C-bar + 3√C-bar

- Decrease Management Restrict (LCL) = C-bar – 3√C-bar

Be aware: If the LCL calculates to a destructive worth, it’s usually set to zero, as you can not have a destructive variety of defects.

-

Plot the Information: Plot the variety of defects (Ci) for every pattern on a chart with a horizontal centerline at C-bar and the calculated UCL and LCL.

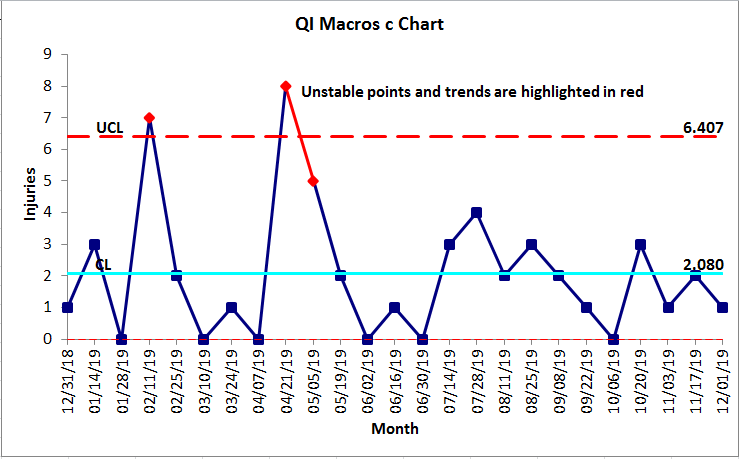

Interpretation of a C-Chart:

-

Factors inside the Management Limits: Signifies the method is in a state of statistical management. The variation noticed is taken into account frequent trigger variation.

-

Factors exterior the Management Limits: Suggests the method is uncontrolled. Particular trigger variation is current, indicating a big change within the course of. Investigation is required to determine and eradicate the basis explanation for this variation.

-

Traits or Patterns: Even when factors stay inside the management limits, persistent traits (e.g., persistently rising or reducing variety of defects) or different patterns (e.g., cyclical variation) point out potential issues that require consideration.

Understanding U-Charts

A U-chart is used when the pattern dimension varies from subgroup to subgroup. The "U" represents the variety of defects per unit. This implies the chart screens the defect fee slightly than absolutely the variety of defects. Examples embrace monitoring the variety of defects per 1000 traces of code in software program improvement (pattern dimension varies by venture), the variety of buyer complaints per 1000 prospects served (pattern dimension varies by month), or the variety of errors per 1000 manufactured components (pattern dimension varies by manufacturing run).

Development of a U-Chart:

-

Information Assortment: Collect information on the variety of defects (Ci) and the corresponding pattern dimension (ni) for every pattern.

-

Calculate the Common Defect Charge: Calculate the typical defect fee (U-bar) throughout all samples.

U-bar = ΣCi / Σni

the place:

- ΣCi = the sum of defects in all samples

- Σni = the sum of pattern sizes throughout all samples

-

Calculate the Management Limits: Much like the C-chart, the management limits are based mostly on the Poisson distribution. The usual deviation of the defect fee is √(U-bar/ni).

- UCL = U-bar + 3√(U-bar/ni)

- LCL = U-bar – 3√(U-bar/ni)

Be aware: The management limits for a U-chart are sample-specific; they differ relying on the pattern dimension (ni). Once more, a destructive LCL is ready to zero.

-

Plot the Information: Plot the defect fee (Ci/ni) for every pattern on a chart with a horizontal centerline at U-bar and the calculated UCL and LCL for every pattern.

Interpretation of a U-Chart:

The interpretation of a U-chart is just like a C-chart. Factors exterior the management limits or non-random patterns inside the limits point out a necessity for investigation to determine and deal with particular trigger variation.

Key Variations between C-Charts and U-Charts:

| Characteristic | C-Chart | U-Chart |

|---|---|---|

| Pattern Measurement | Fixed | Variable |

| Metric | Variety of defects | Defect fee (defects per unit) |

| Management Limits | Fixed | Variable (depending on pattern dimension) |

| Software | Fixed pattern dimension, defect depend | Variable pattern dimension, defect fee |

Selecting between C-Charts and U-Charts:

The selection between a C-chart and a U-chart relies upon totally on the character of the information. If the pattern dimension is fixed, a C-chart is acceptable. If the pattern dimension varies, a U-chart is important. Utilizing the mistaken chart can result in inaccurate conclusions about course of stability.

Limitations of C-Charts and U-Charts:

-

Assumption of Randomness: Each charts assume that defects happen randomly and independently. If defects are clustered or correlated, the management limits could also be deceptive.

-

Sensitivity to Small Samples: With very small pattern sizes, the management limits could be extensive, making it tough to detect small shifts within the course of.

-

Non-normality: Whereas the Poisson distribution is usually an excellent approximation, it may not be completely correct for all sorts of depend information.

-

Ignoring Defect Severity: Each charts deal with all defects equally, no matter their severity. A weighted method may be extra acceptable in some conditions.

Conclusion:

C-charts and U-charts are helpful instruments for monitoring processes the place the first concern is the variety of defects. Their capacity to deal with variable pattern sizes makes them extremely versatile and relevant throughout a variety of industries and purposes. Nevertheless, it is essential to grasp their assumptions and limitations to make sure correct interpretation and efficient course of enchancment. Correct information assortment, cautious chart development, and an intensive understanding of statistical rules are important for maximizing the advantages of those highly effective SPC instruments. All the time keep in mind to research any out-of-control alerts to determine and eradicate the basis causes of variation and enhance course of efficiency.

Closure

Thus, we hope this text has offered helpful insights into C-Charts and U-Charts: Monitoring Defects in Variable-Sized Samples. We thanks for taking the time to learn this text. See you in our subsequent article!