Decoding the 410A Piston Orifice Chart: A Complete Information for HVAC Technicians

Associated Articles: Decoding the 410A Piston Orifice Chart: A Complete Information for HVAC Technicians

Introduction

On this auspicious event, we’re delighted to delve into the intriguing matter associated to Decoding the 410A Piston Orifice Chart: A Complete Information for HVAC Technicians. Let’s weave attention-grabbing info and provide contemporary views to the readers.

Desk of Content material

Decoding the 410A Piston Orifice Chart: A Complete Information for HVAC Technicians

Refrigerant 410A, a broadly adopted mix in air-con and refrigeration methods, calls for exact metering of refrigerant circulation for optimum efficiency and effectivity. A vital part in attaining this accuracy is the piston orifice, a kind of metering system that makes use of a exactly machined piston to control the refrigerant circulation fee. Understanding the intricacies of a 410A piston orifice chart is important for HVAC technicians, enabling them to pick out the proper orifice for particular system necessities and troubleshoot efficiency points.

This text delves deep into the complexities of 410A piston orifice charts, explaining their construction, deciphering the information introduced, and highlighting their significance in system design and upkeep. We can even discover the components influencing orifice choice and the potential penalties of improper orifice sizing.

Understanding Piston Orifice Operate and Building

Earlier than diving into chart interpretation, it is essential to grasp the elemental perform of a piston orifice. In contrast to growth valves, which make the most of strain differentials to control circulation, a piston orifice depends on a hard and fast restriction. The piston, exactly fitted inside a cylinder, creates a calibrated opening that determines the refrigerant circulation fee. This circulation fee is instantly influenced by the strain distinction throughout the orifice and the dimensions of the orifice opening.

The development of a piston orifice is comparatively easy but exact. It sometimes consists of:

- A exactly machined piston: This piston is often constructed from sturdy supplies proof against refrigerant corrosion. The diameter of the piston dictates the dimensions of the orifice opening.

- A cylinder: The piston slides inside this cylinder, creating the restriction. The cylinder is rigorously designed to make sure a decent seal and decrease leakage.

- A spring (in some designs): Some piston orifices incorporate a spring to offer a level of adjustment or to help in sustaining a constant seal.

- Exterior threads: These threads enable for straightforward set up and elimination from the system.

Deciphering the 410A Piston Orifice Chart

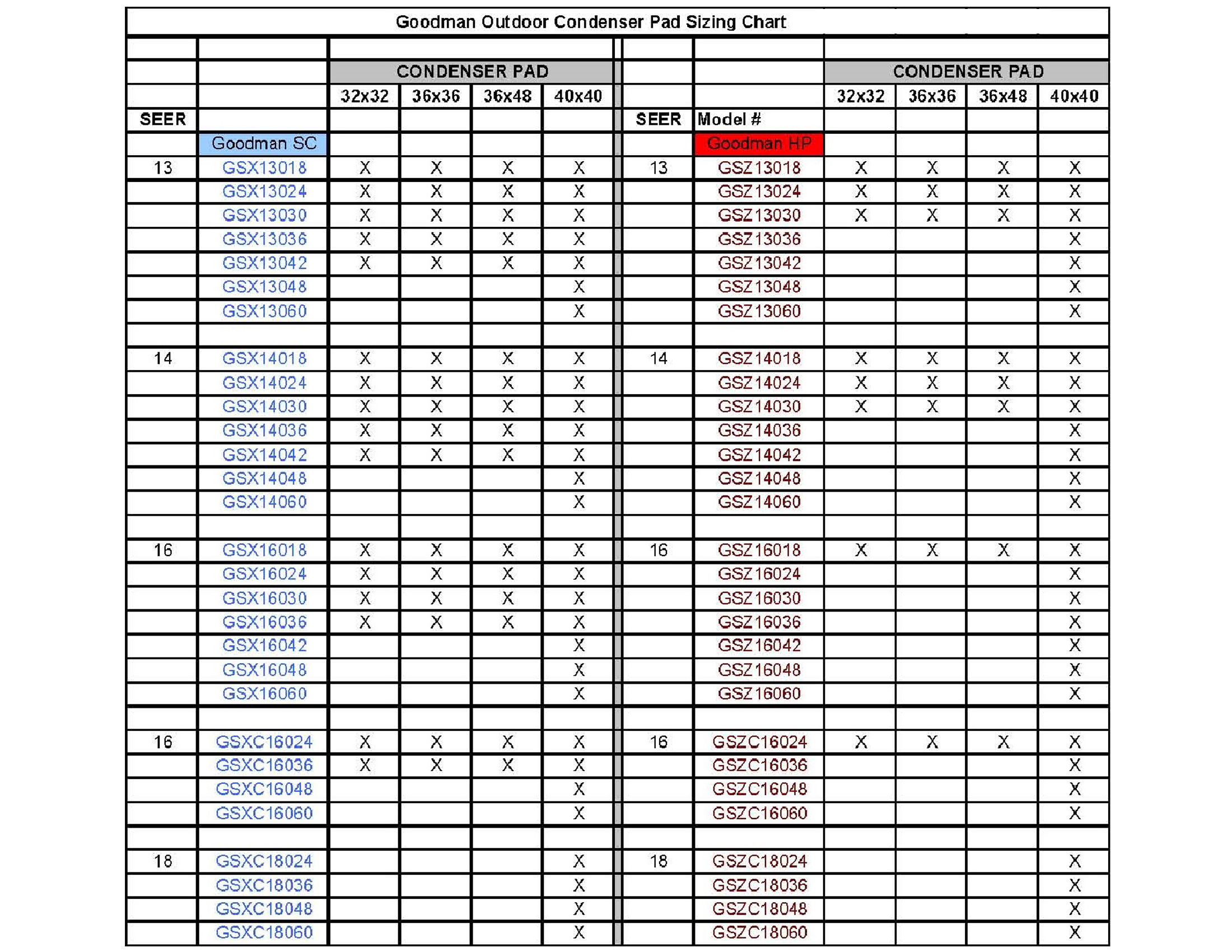

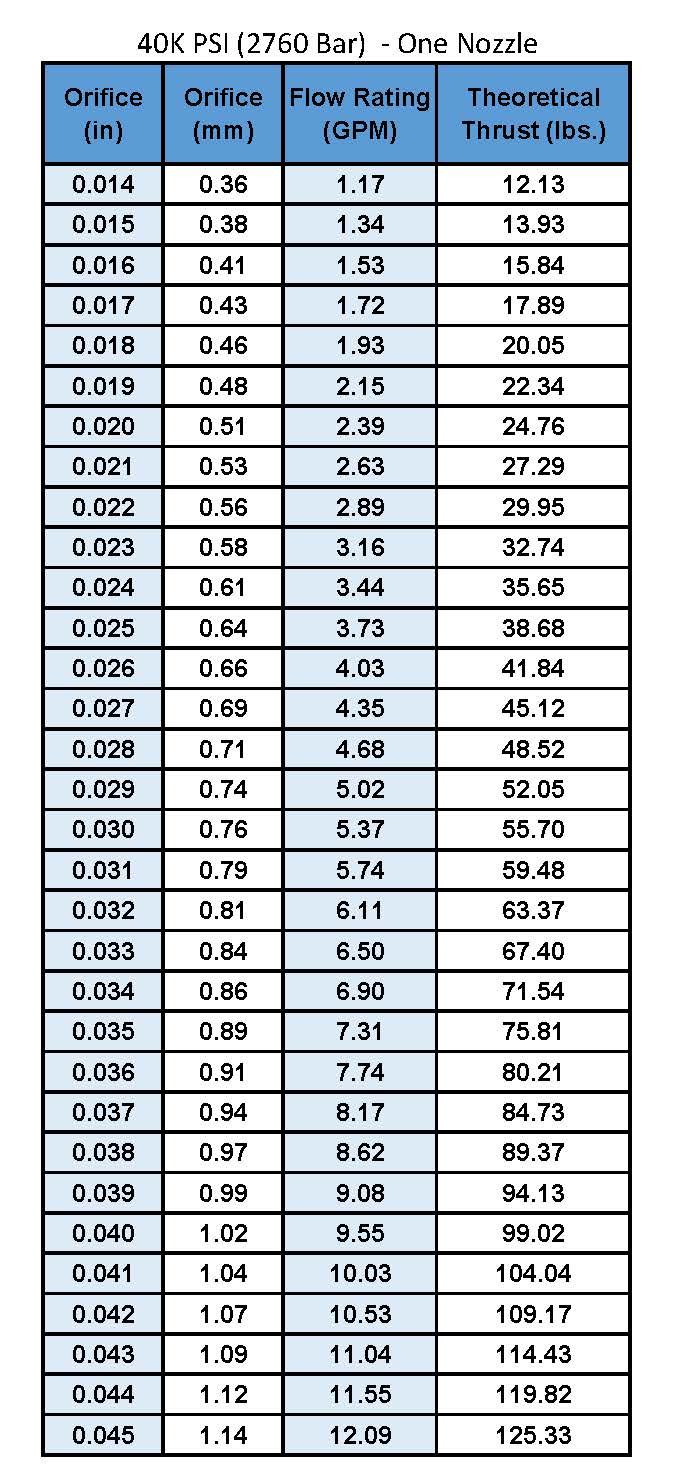

A 410A piston orifice chart is a tabular or graphical illustration correlating numerous system parameters with the suitable orifice measurement. These charts are sometimes offered by producers and are important instruments for choosing the proper orifice for a given software. Whereas the precise format can fluctuate between producers, the elemental info stays constant:

- Refrigerant Sort: This can explicitly state that the chart is for 410A refrigerant. Utilizing a chart designed for a special refrigerant will result in inaccurate outcomes and potential system harm.

- System Capability (BTU/hr or kW): This represents the cooling capability of the air-con or refrigeration system. The chart will sometimes record a variety of capacities.

- Evaporating Temperature (°F or °C): That is the temperature of the refrigerant because it evaporates within the evaporator coil. Decrease evaporating temperatures usually require bigger orifices.

- Condensing Temperature (°F or °C): That is the temperature of the refrigerant because it condenses within the condenser. Greater condensing temperatures sometimes necessitate smaller orifices.

- Superheat (°F or °C): Superheat is the temperature distinction between the refrigerant leaving the evaporator and the evaporating temperature. Correct superheat is essential for system effectivity and stopping liquid refrigerant from coming into the compressor. The chart could instantly record superheat values or present steerage on attaining the specified superheat.

- Subcooling (°F or °C): Subcooling is the temperature distinction between the refrigerant leaving the condenser and the condensing temperature. Sufficient subcooling is essential for stopping vapor within the liquid line. The chart could embrace subcooling values or directions for attaining optimum subcooling.

- Piston Orifice Dimension (diameter or circulation fee): That is the core info offered by the chart. It signifies the suitable piston orifice diameter or circulation fee in models like millimeters (mm) or cubic centimeters per minute (cc/min) comparable to the desired system parameters.

Components Influencing Orifice Choice

A number of components past the essential system parameters affect the collection of the suitable 410A piston orifice:

- System Design: The general system design, together with the kind of evaporator and condenser coils, the size and diameter of the refrigerant traces, and the presence of any warmth exchangers, considerably impression refrigerant circulation necessities.

- Ambient Circumstances: The ambient temperature and humidity can have an effect on the condensing temperature and, consequently, the required orifice measurement.

- Altitude: Altitude impacts the boiling level of the refrigerant, influencing the evaporating temperature and the mandatory orifice measurement. Charts for high-altitude functions could also be particularly offered.

- Line Set Size and Diameter: Longer and smaller-diameter refrigerant traces improve the strain drop, requiring a barely bigger orifice to keep up the specified circulation fee.

- Compressor Effectivity: The effectivity of the compressor can affect the refrigerant circulation necessities. A extra environment friendly compressor could require a barely smaller orifice.

Penalties of Incorrect Orifice Sizing

Selecting an incorrectly sized piston orifice can have severe penalties for the HVAC system’s efficiency and longevity:

- Undersized Orifice: An undersized orifice restricts refrigerant circulation excessively. This will result in diminished cooling capability, elevated compressor discharge temperature, and potential compressor harm on account of overheating. The system can also exhibit frosting on the evaporator coil on account of inadequate refrigerant circulation.

- Outsized Orifice: An outsized orifice permits extreme refrigerant circulation. This can lead to liquid refrigerant slugging into the compressor, inflicting severe harm and potential system failure. It might probably additionally result in diminished system effectivity and elevated power consumption.

Utilizing the Chart and Troubleshooting

To make use of a 410A piston orifice chart successfully, comply with these steps:

- Collect System Knowledge: Precisely measure the system’s cooling capability, evaporating temperature, condensing temperature, superheat, and subcooling. Think about the ambient situations and altitude.

- Find the Applicable Part: Discover the part of the chart comparable to the refrigerant sort (410A).

- Determine the Appropriate Orifice Dimension: Utilizing the gathered knowledge, find the intersection of the related parameters on the chart to find out the really helpful orifice measurement.

- Set up and Check: Fastidiously set up the chosen orifice and totally take a look at the system to confirm its efficiency. Monitor the superheat and subcooling to make sure they’re throughout the really helpful ranges.

If the system is just not performing optimally after orifice set up, contemplate the next troubleshooting steps:

- Re-check System Parameters: Make sure the preliminary measurements had been correct.

- Confirm Orifice Set up: Make sure the orifice is appropriately put in and free from obstructions.

- Verify for Leaks: Examine the system for any refrigerant leaks that might have an effect on efficiency.

- Consider Different Parts: Think about potential points with the compressor, condenser, evaporator, or different system parts.

Conclusion

The 410A piston orifice chart is a essential software for HVAC technicians concerned within the design, set up, and upkeep of air-con and refrigeration methods utilizing 410A refrigerant. Understanding the chart’s construction, deciphering the information, and contemplating the assorted components influencing orifice choice are essential for guaranteeing optimum system efficiency, effectivity, and longevity. Correct orifice sizing prevents potential harm to the compressor and different parts, contributing to the general reliability and cost-effectiveness of the system. By mastering using the 410A piston orifice chart, technicians can considerably improve their troubleshooting abilities and supply superior service to their purchasers. Keep in mind at all times to seek the advice of the producer’s particular charts and pointers for probably the most correct and dependable outcomes.

Closure

Thus, we hope this text has offered worthwhile insights into Decoding the 410A Piston Orifice Chart: A Complete Information for HVAC Technicians. We recognize your consideration to our article. See you in our subsequent article!