Decoding the Copper Sort Okay Measurement Chart: A Complete Information for Professionals and Fans

Associated Articles: Decoding the Copper Sort Okay Measurement Chart: A Complete Information for Professionals and Fans

Introduction

With enthusiasm, let’s navigate by the intriguing subject associated to Decoding the Copper Sort Okay Measurement Chart: A Complete Information for Professionals and Fans. Let’s weave attention-grabbing data and supply contemporary views to the readers.

Desk of Content material

Decoding the Copper Sort Okay Measurement Chart: A Complete Information for Professionals and Fans

Copper Sort Okay tubing, a ubiquitous fixture in numerous industries, calls for an intensive understanding of its sizing conventions. This text dives deep into the intricacies of the Sort Okay copper measurement chart, explaining its significance, the totally different sizing techniques used, and the sensible implications of choosing the suitable measurement to your utility. We’ll discover the nuances of nominal measurement, exterior diameter (OD), inside diameter (ID), wall thickness, and the way these components affect stress rankings, stream charges, and total system efficiency.

Understanding Sort Okay Copper Tubing:

Sort Okay copper tubing is a inflexible, annealed copper pipe particularly designed for refrigeration and air-con functions. Its composition, usually 99.9% pure copper, offers glorious corrosion resistance, thermal conductivity, and ductility. The "Okay" designation refers to a particular wall thickness commonplace, guaranteeing constant efficiency and reliability throughout the HVAC/R trade. This standardization is essential for guaranteeing compatibility with fittings and different parts throughout the system.

Sizing Techniques and Their Significance:

Navigating the Sort Okay copper measurement chart requires familiarity with the totally different sizing techniques employed. The commonest are:

-

Nominal Measurement (NPS): That is probably the most incessantly used system, representing an approximate inner diameter. It is vital to know that the NPS shouldn’t be the precise inside diameter; it’s a historic designation that does not instantly correspond to specific measurements. For instance, a 1/2" NPS pipe does not have an inside diameter of precisely 0.5 inches.

-

Exterior Diameter (OD): This refers back to the precise exterior diameter of the tubing. It is a essential measurement for becoming choice, as fittings are manufactured to accommodate particular ODs. The OD stays comparatively constant throughout totally different wall thicknesses for a given nominal measurement.

-

Inside Diameter (ID): That is the interior diameter of the tubing, instantly impacting the stream price of the refrigerant or different fluids throughout the system. The ID is smaller than the NPS and is affected by the wall thickness. A thicker wall (e.g., heavier gauge) will lead to a smaller ID for a similar nominal measurement.

-

Wall Thickness (WT): That is the thickness of the copper materials that constitutes the pipe wall. It is a essential issue influencing the stress score and total power of the tubing. Thicker partitions can face up to greater pressures however might limit stream. Sort Okay copper tubing has a particular wall thickness for every nominal measurement, as outlined by trade requirements.

The Sort Okay Copper Measurement Chart: A Detailed Examination:

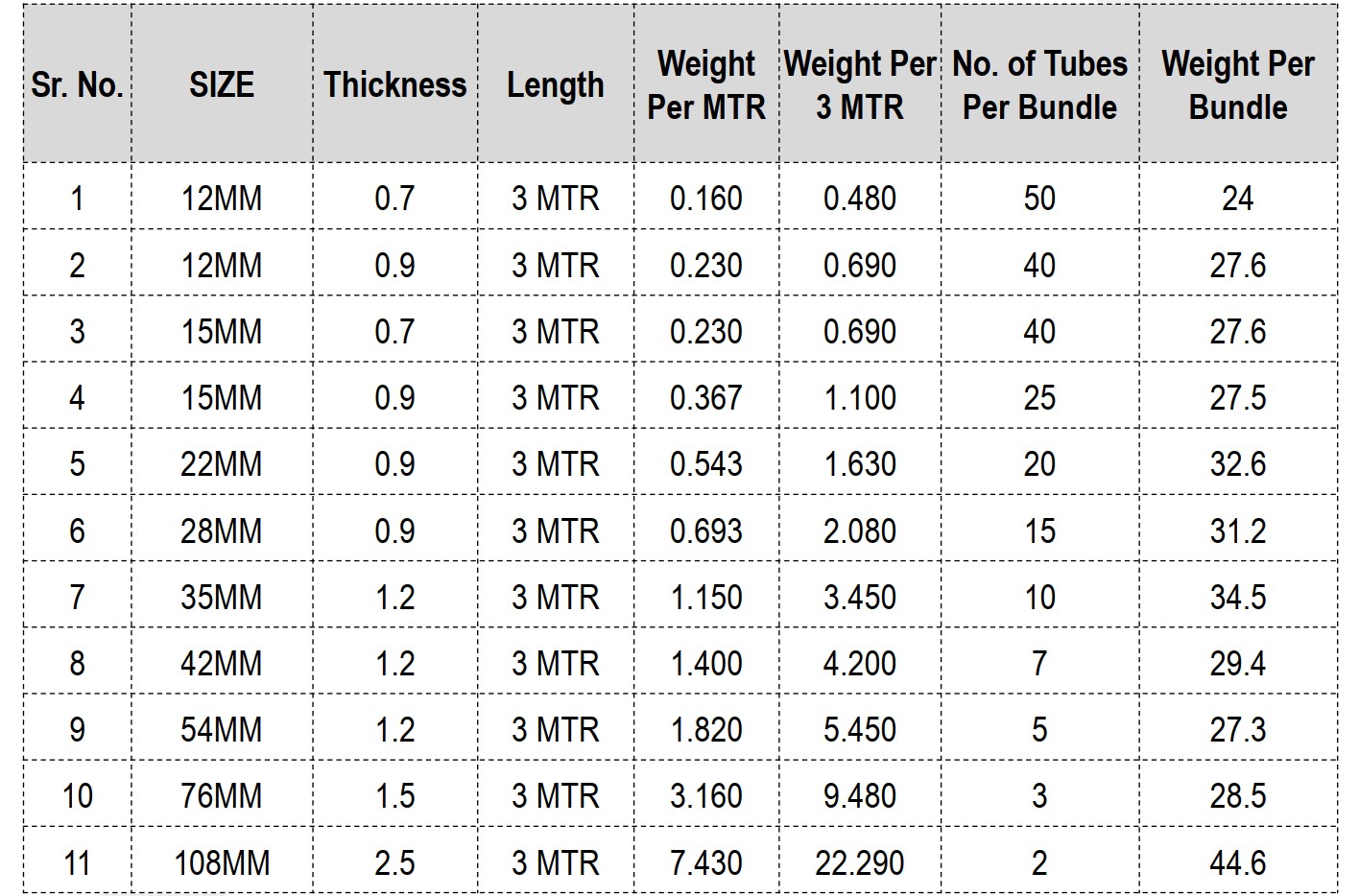

The next desk offers a pattern illustration of a Sort Okay copper measurement chart. Notice that particular dimensions might differ barely relying on the producer and relevant requirements. At all times seek the advice of the producer’s specs for probably the most correct information.

| Nominal Measurement (NPS) | Exterior Diameter (OD) (inches) | Inside Diameter (ID) (inches) | Wall Thickness (WT) (inches) | Approximate Weight per Foot (lbs) |

|---|---|---|---|---|

| 1/4" | 0.375 | 0.280 | 0.0475 | 0.16 |

| 3/8" | 0.500 | 0.396 | 0.052 | 0.26 |

| 1/2" | 0.625 | 0.500 | 0.0625 | 0.42 |

| 3/4" | 0.875 | 0.700 | 0.0875 | 0.75 |

| 1" | 1.125 | 0.955 | 0.085 | 1.11 |

| 1-1/4" | 1.375 | 1.150 | 0.1125 | 1.61 |

| 1-1/2" | 1.625 | 1.380 | 0.1225 | 2.20 |

| 2" | 2.125 | 1.900 | 0.1125 | 3.65 |

| 2-1/2" | 2.625 | 2.375 | 0.125 | 5.76 |

| 3" | 3.125 | 2.875 | 0.125 | 8.20 |

Deciphering the Chart and Its Implications:

The chart illustrates the connection between nominal measurement, OD, ID, and wall thickness. Understanding these relationships is essential for a number of causes:

-

Stress Ranking: Thicker partitions (bigger WT) lead to greater stress rankings. Selecting the suitable measurement is essential for guaranteeing the system can face up to the working pressures. Inadequate wall thickness can result in leaks and even catastrophic failures.

-

Circulation Fee: The ID instantly impacts the stream price of the refrigerant. A smaller ID will limit stream, probably impacting system effectivity. Overly giant tubing can result in elevated refrigerant cost and diminished effectivity.

-

Becoming Choice: The OD dictates the kind of fittings that can be utilized. Utilizing incorrect fittings can result in leaks and system malfunctions.

-

Weight and Dealing with: The burden per foot is vital for estimating materials prices and dealing with issues, particularly for bigger diameter tubing.

Components to Take into account When Selecting Sort Okay Copper Measurement:

Deciding on the proper measurement Sort Okay copper tubing entails contemplating a number of components past the dimensions chart:

-

Refrigerant Sort and Cost: Totally different refrigerants have various properties, impacting the required stream price and stress. The refrigerant cost considerably influences the system’s working stress.

-

System Size and Configuration: Longer runs and complicated configurations might require bigger diameter tubing to compensate for stress drop.

-

Working Temperature and Stress: The working situations instantly affect the required stress score and the fabric choice.

-

Code Compliance: Native constructing codes and trade requirements dictate minimal necessities for tubing measurement and stress rankings. Adherence to those codes is essential for security and compliance.

-

Value Optimization: Balancing the price of supplies with system effectivity and efficiency is essential. Oversizing tubing could be unnecessarily costly, whereas undersizing can compromise efficiency and reliability.

Past the Chart: Superior Concerns:

Whereas the dimensions chart offers elementary data, a number of superior issues affect tubing choice:

-

Growth and Contraction: Copper expands and contracts with temperature fluctuations. Correct design and set up strategies should account for these modifications to stop stress on the system.

-

Bending Radius: Sort Okay copper tubing has a minimal bending radius that should be adhered to throughout set up to stop kinking or harm.

-

Corrosion and Environmental Components: Whereas Sort Okay copper affords glorious corrosion resistance, sure environmental situations might require extra safety measures.

-

Brazing and Becoming a member of Methods: Correct brazing strategies are essential for creating leak-free joints. Incorrect procedures can compromise the integrity of the system.

Conclusion:

The Sort Okay copper measurement chart is a necessary software for professionals and fans working with refrigeration and air-con techniques. Understanding the nuances of nominal measurement, OD, ID, and wall thickness, coupled with an intensive consideration of the components outlined on this article, is essential for choosing the suitable tubing measurement for optimum efficiency, security, and longevity. At all times seek advice from producer specs and related trade requirements for exact dimensions and stress rankings. Correct sizing shouldn’t be merely a matter of comfort; it is a elementary side of guaranteeing a dependable and environment friendly HVAC/R system.

Closure

Thus, we hope this text has supplied useful insights into Decoding the Copper Sort Okay Measurement Chart: A Complete Information for Professionals and Fans. We thanks for taking the time to learn this text. See you in our subsequent article!