Decoding the Machine: A Complete Information to G-Code and M-Code Charts

Associated Articles: Decoding the Machine: A Complete Information to G-Code and M-Code Charts

Introduction

With enthusiasm, let’s navigate via the intriguing matter associated to Decoding the Machine: A Complete Information to G-Code and M-Code Charts. Let’s weave attention-grabbing data and supply contemporary views to the readers.

Desk of Content material

Decoding the Machine: A Complete Information to G-Code and M-Code Charts

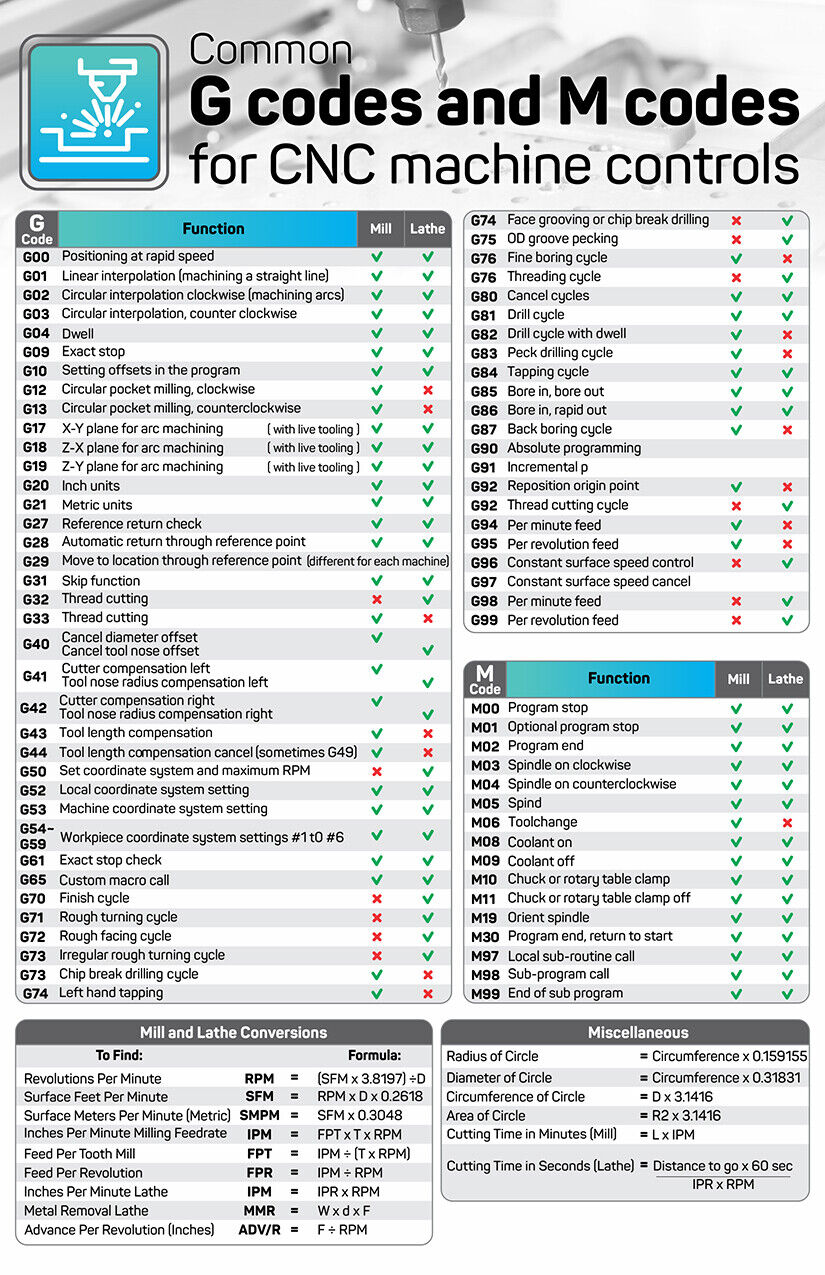

CNC machining, the method of eradicating materials from a workpiece utilizing computer-controlled instruments, depends closely on a exact language understood by the machine: G-code and M-code. These codes, basically directions written in a particular format, dictate each facet of the machining course of, from the software’s motion to the spindle’s pace and coolant activation. Understanding these codes is essential for anybody concerned in CNC programming, operation, and even upkeep. This text gives a complete information to G-code and M-code charts, explaining their capabilities, widespread instructions, and the significance of their exact utility.

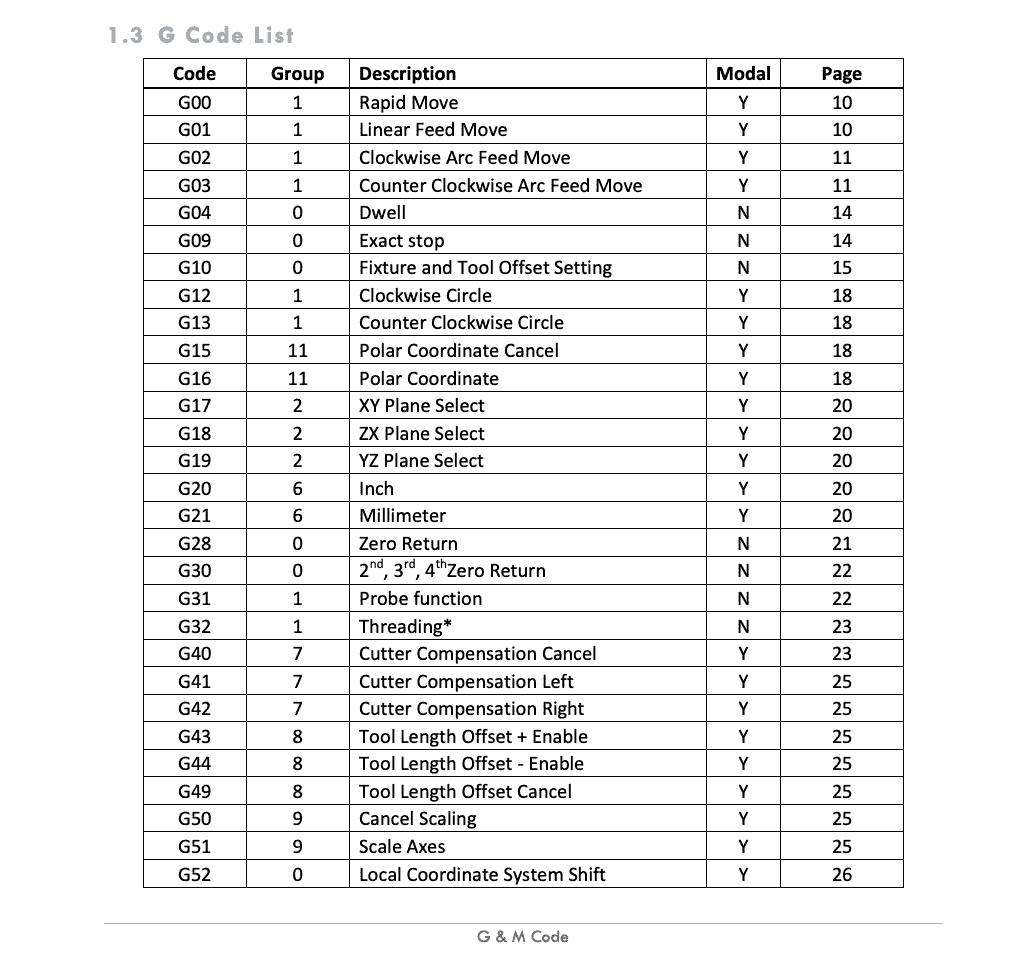

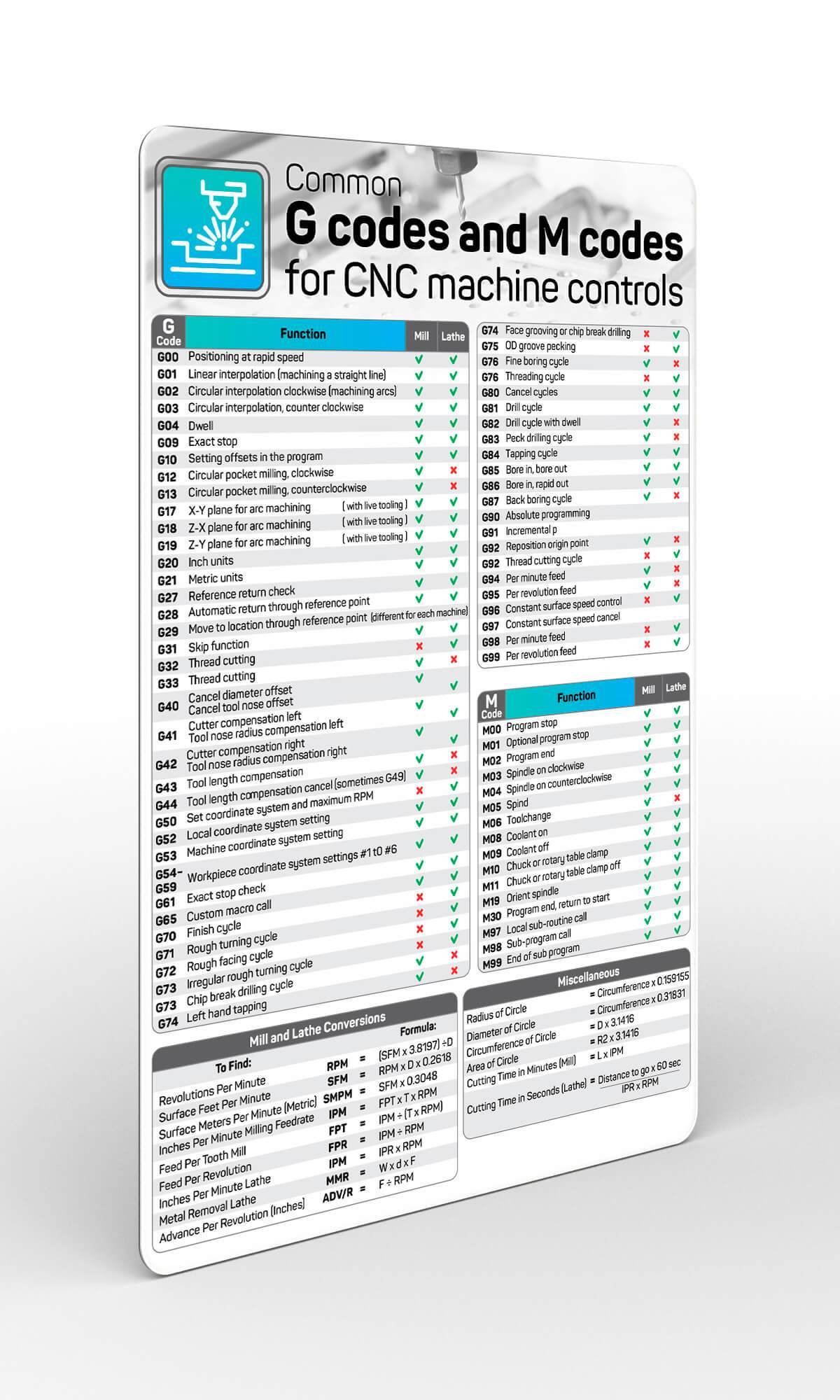

G-Code: The Geometry of Machining

G-code, often known as preparatory codes, governs the geometry of the machining course of. It dictates the trail the software will take, its pace, and the feed fee. Completely different G-codes provoke numerous capabilities, and their parameters specify the main points. Understanding these codes is the muse of making environment friendly and correct CNC applications. Whereas the precise instructions can range barely relying on the CNC machine’s controller (e.g., Fanuc, Siemens, Haas), the core ideas stay constant. This is a breakdown of some important G-codes:

-

G00 (Fast Positioning): This code strikes the software quickly to a specified place with out performing any chopping. It is primarily used for positioning the software earlier than a chopping operation or transferring it to a protected location. Velocity is normally maximized throughout G00 actions.

-

G01 (Linear Interpolation): That is the most typical chopping code, performing linear actions whereas the software is chopping. It requires specifying the goal coordinates (X, Y, Z) and the feed fee (F). The software strikes in a straight line from its present place to the required coordinates on the outlined feed fee.

-

G02 (Round Interpolation, Clockwise): This code generates a round arc in a clockwise route. It requires specifying the top level coordinates (X, Y), the middle level coordinates (I, J), and the feed fee (F). The I and J values signify the offsets from the present place to the middle of the arc.

-

G03 (Round Interpolation, Counter-Clockwise): Much like G02, this code creates a round arc however in a counter-clockwise route. It makes use of the identical parameters (X, Y, I, J, F).

-

G04 (Dwell): This code introduces a pause in this system for a specified period of time, normally measured in seconds. That is helpful for permitting coolant to achieve the chopping space or for different timed processes.

-

G90 (Absolute Programming): This code units the coordinate system to absolute programming. All subsequent X, Y, and Z coordinates are specified relative to the machine’s origin (0, 0, 0).

-

G91 (Incremental Programming): This code switches to incremental programming. Coordinates are specified relative to the software’s present place. That is helpful for repetitive operations.

-

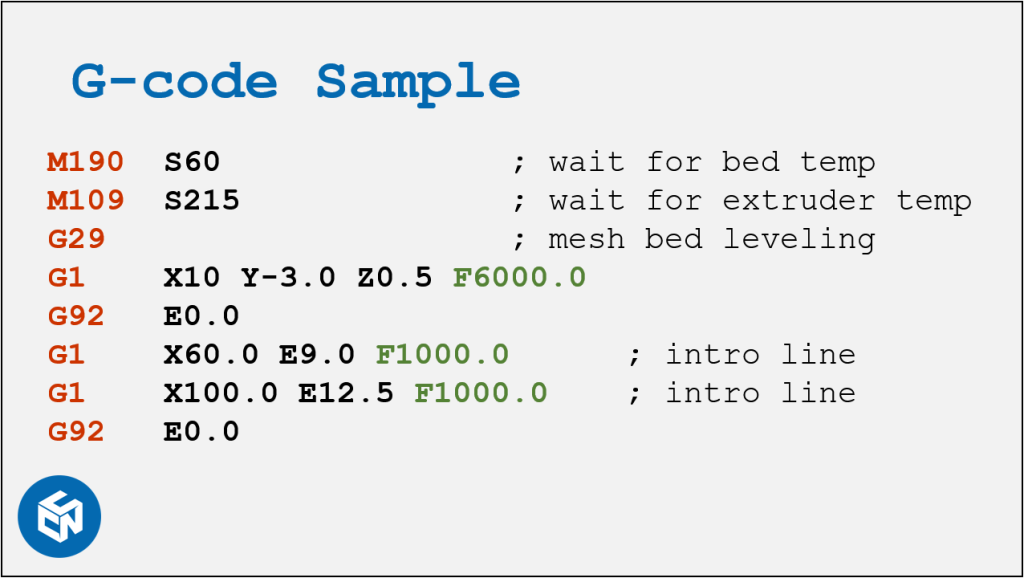

G92 (Coordinate Setting): This code permits the programmer to set a brand new coordinate system origin. That is useful for outlining sub-programs or working with advanced elements.

-

G28 (Return to Residence): This code returns the software to its house place, a pre-defined protected location normally set by the machine operator.

-

G21 (Metric Models): Specifies that every one subsequent dimensions might be in millimeters.

-

G20 (Inch Models): Specifies that every one subsequent dimensions might be in inches.

M-Code: Machine Management Instructions

M-codes, or miscellaneous codes, management numerous machine capabilities unrelated to toolpath geometry. They deal with features like spindle management, coolant activation, software adjustments, and program termination. Much like G-codes, M-codes can range barely between totally different CNC controllers. Listed here are some important M-codes:

-

M00 (Program Cease): This code causes the machine to cease execution of this system, permitting the operator to examine the workpiece or make changes.

-

M01 (Non-obligatory Cease): This code gives an non-compulsory cease, which will be bypassed by the operator.

-

M02 (Program Finish): This code indicators the top of this system and returns the machine to its idle state. It is essential for correct program termination.

-

M03 (Spindle On, Clockwise): This code begins the spindle rotating clockwise. The spindle pace (S) is normally specified as a parameter.

-

M04 (Spindle On, Counter-Clockwise): This code begins the spindle rotating counter-clockwise.

-

M05 (Spindle Cease): This code stops the spindle rotation.

-

M06 (Software Change): This code initiates a software change. The particular software quantity is normally specified as a parameter.

-

M08 (Coolant On): Prompts the coolant system.

-

M09 (Coolant Off): Deactivates the coolant system.

-

M30 (Program Finish and Reset): This code ends this system and resets the machine to its preliminary state, much like M02 however with an added reset perform.

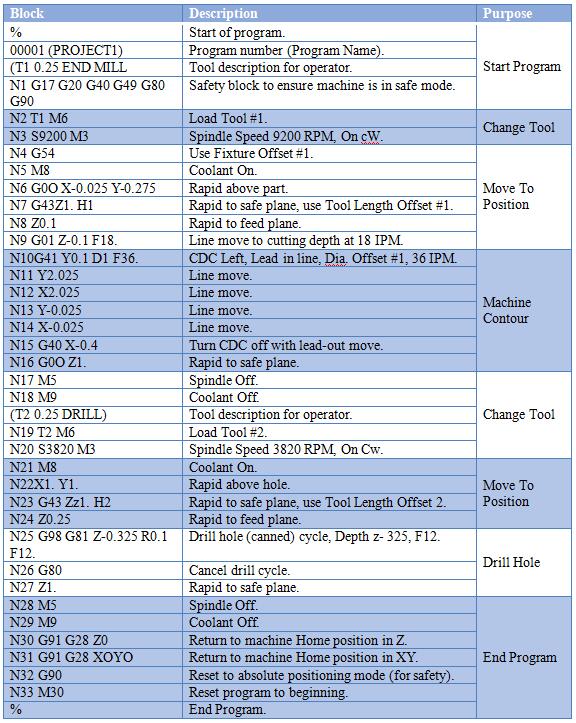

Creating and Understanding G-Code and M-Code Charts

G-code and M-code charts are important instruments for CNC programmers and operators. These charts present a transparent and concise reference for all of the codes utilized in a particular program or machine. They sometimes embody:

- Code: The G-code or M-code itself.

- Perform: A short description of the code’s perform.

- Parameters: Any parameters required by the code (e.g., X, Y, Z, F, S).

- Models: The models used for the parameters (e.g., millimeters, inches).

- Instance: An instance of how the code is utilized in a program.

Making a G-code and M-code chart entails rigorously documenting each code utilized in a program. That is essential for debugging, troubleshooting, and understanding this system’s logic. Many CAM (Laptop-Aided Manufacturing) software program packages routinely generate G-code, however understanding the underlying codes remains to be important for optimization and error correction.

Sensible Functions and Concerns

The efficient use of G-code and M-code charts extends past easy program understanding. They’re integral for:

- Program Debugging: If a program malfunctions, a well-organized chart permits for fast identification of problematic codes.

- Program Modification: Modifying current applications turns into considerably simpler with a transparent understanding of the codes and their capabilities.

- Machine Coaching: Charts are invaluable coaching instruments for brand spanking new CNC operators, offering a structured technique to be taught the machine’s language.

- Upkeep and Troubleshooting: Understanding the codes helps in diagnosing and resolving machine points associated to program execution.

- Collaboration: Charts facilitate collaboration amongst programmers, operators, and engineers, making certain everyone seems to be on the identical web page.

Conclusion:

G-code and M-code are the foundational languages of CNC machining. Mastering these codes, aided by well-structured charts, is important for anybody concerned on this subject. Whereas the particular codes and their parameters might range barely between totally different CNC controllers, the underlying ideas stay constant. An intensive understanding of those codes, coupled with using complete charts, empowers customers to program, function, and preserve CNC machines effectively and precisely, in the end resulting in greater productiveness and improved product high quality. Continued studying and observe are key to turning into proficient on this vital facet of contemporary manufacturing. Bear in mind to all the time seek the advice of your particular machine’s handbook for the exact interpretation of G-codes and M-codes, as variations can exist between totally different producers and controller varieties.

Closure

Thus, we hope this text has offered invaluable insights into Decoding the Machine: A Complete Information to G-Code and M-Code Charts. We hope you discover this text informative and helpful. See you in our subsequent article!