Decoding the Metric Shoulder Bolt Measurement Chart: A Complete Information

Associated Articles: Decoding the Metric Shoulder Bolt Measurement Chart: A Complete Information

Introduction

With nice pleasure, we are going to discover the intriguing matter associated to Decoding the Metric Shoulder Bolt Measurement Chart: A Complete Information. Let’s weave fascinating info and supply recent views to the readers.

Desk of Content material

Decoding the Metric Shoulder Bolt Measurement Chart: A Complete Information

Shoulder bolts, characterised by their cylindrical shoulder beneath the bolt head, supply a novel mixture of energy and exact positioning. Continuously utilized in functions requiring a flush or near-flush mounting floor, they’re indispensable in numerous industries, from automotive and manufacturing to building and aerospace. Understanding metric shoulder bolt dimension charts is essential for choosing the proper fastener for a given software, guaranteeing each structural integrity and an expert end. This text gives an in depth exploration of metric shoulder bolt sizing, together with dimensions, tolerances, materials specs, and software issues.

Understanding the Fundamentals of Metric Shoulder Bolt Dimensions

Metric shoulder bolts are outlined by a sequence of key dimensions, all expressed in millimeters (mm). These dimensions are crucial for guaranteeing correct match and performance. The first dimensions embrace:

-

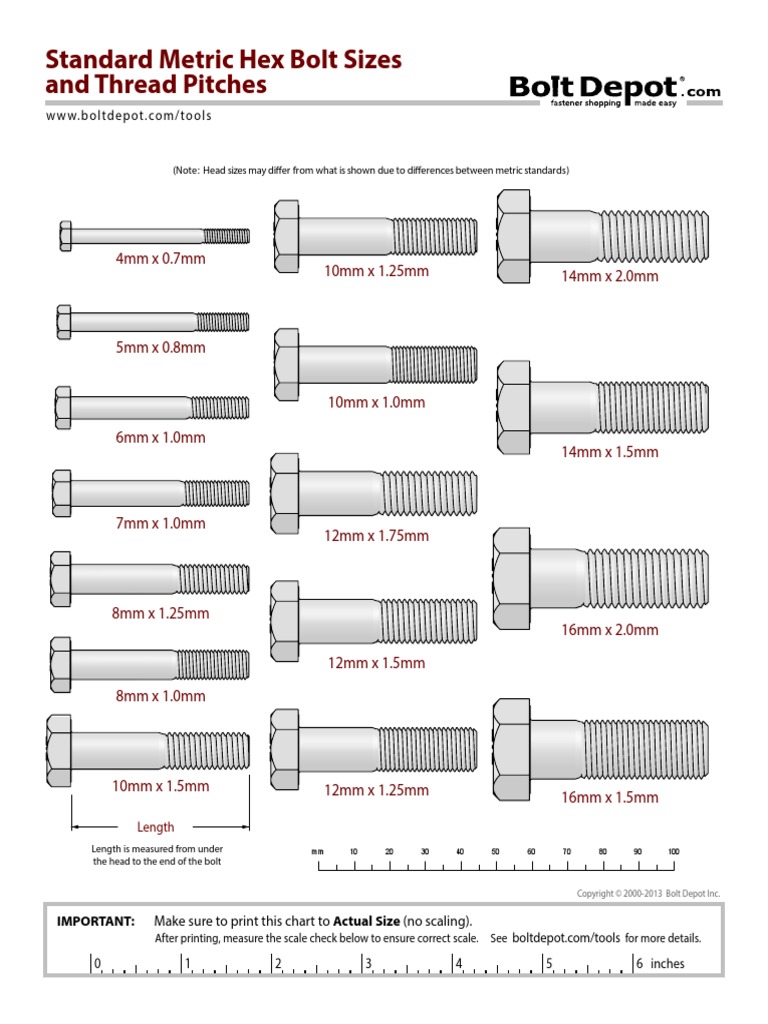

Nominal Diameter (d): This refers back to the diameter of the threaded portion of the bolt. It is probably the most essential dimension and is normally the primary quantity laid out in a dimension designation (e.g., M6, M8, M10). The "M" denotes the metric system.

-

Thread Pitch (P): That is the space between adjoining thread crests. The pitch is commonly implicitly outlined by the nominal diameter, although it may be explicitly acknowledged (e.g., M6 x 1.0, indicating a 6mm diameter with a 1.0mm pitch). Totally different pitches can be found for every diameter, affecting the bolt’s energy and software suitability.

-

Shoulder Diameter (D): That is the diameter of the unthreaded cylindrical shoulder. It is bigger than the nominal diameter, offering a bigger bearing floor and sometimes contributing to a extra sturdy and aesthetically pleasing connection.

-

Shoulder Size (Ls): That is the size of the unthreaded shoulder. This dimension is crucial for correct match and guaranteeing the shoulder sits flush or recessed as required.

-

Bolt Size (L): That is the general size of the bolt, together with each the threaded and unthreaded parts. It is essential to decide on a bolt size that gives adequate thread engagement into the mating part.

-

Head Kind and Dimensions: Shoulder bolts are available in numerous head varieties, together with hex head, button head, socket head cap screws (sometimes called Allen head screws), and others. The top dimensions (peak, width throughout flats for hex heads) are additionally essential for correct wrench choice and set up.

-

Materials: The fabric of the bolt considerably impacts its energy, corrosion resistance, and suitability for particular functions. Widespread supplies embrace metal (numerous grades), stainless-steel (numerous grades), brass, and aluminum.

Decoding a Metric Shoulder Bolt Measurement Chart

A typical metric shoulder bolt dimension chart will checklist the above dimensions for numerous bolt sizes. The chart could also be organized by nominal diameter, permitting you to rapidly discover bolts inside a selected dimension vary. As an example, a chart may checklist the next info for an M8 shoulder bolt:

| Nominal Diameter (d) | Thread Pitch (P) | Shoulder Diameter (D) | Shoulder Size (Ls) | Bolt Size (L) | Materials | Head Kind |

|---|---|---|---|---|---|---|

| M8 | 1.25 | 12 | 10 | 25 | Metal (Grade 8.8) | Hex Head |

This entry signifies an M8 shoulder bolt with a 1.25mm pitch, a 12mm shoulder diameter, a 10mm shoulder size, a complete size of 25mm, manufactured from Grade 8.8 metal, and that includes a hex head. A number of entries for a similar nominal diameter will present variations in shoulder size, total size, and materials.

Choosing the Proper Metric Shoulder Bolt:

Selecting the suitable metric shoulder bolt entails fastidiously contemplating a number of components:

-

Utility Necessities: The meant software dictates the required energy, corrosion resistance, and total dimensions. Excessive-stress functions demand high-strength supplies and acceptable bolt sizes.

-

Materials Compatibility: The bolt materials should be suitable with the supplies of the elements it is connecting. Think about components like galvanic corrosion.

-

Thread Engagement: Guarantee adequate thread engagement to attain the mandatory clamping power. Inadequate thread engagement can result in untimely failure.

-

Shoulder Size and Diameter: The shoulder size and diameter should be appropriate for the applying. The shoulder ought to present satisfactory bearing floor and permit for correct positioning.

-

Head Kind and Measurement: Choose a head kind and dimension that permits for simple set up and gives adequate torque capability.

Tolerance Issues:

Metric shoulder bolt dimensions are topic to manufacturing tolerances. These tolerances outline the permissible variations in dimensions. Understanding these tolerances is essential for guaranteeing correct match and performance. Tolerance requirements are usually specified in response to ISO requirements.

Materials Specs:

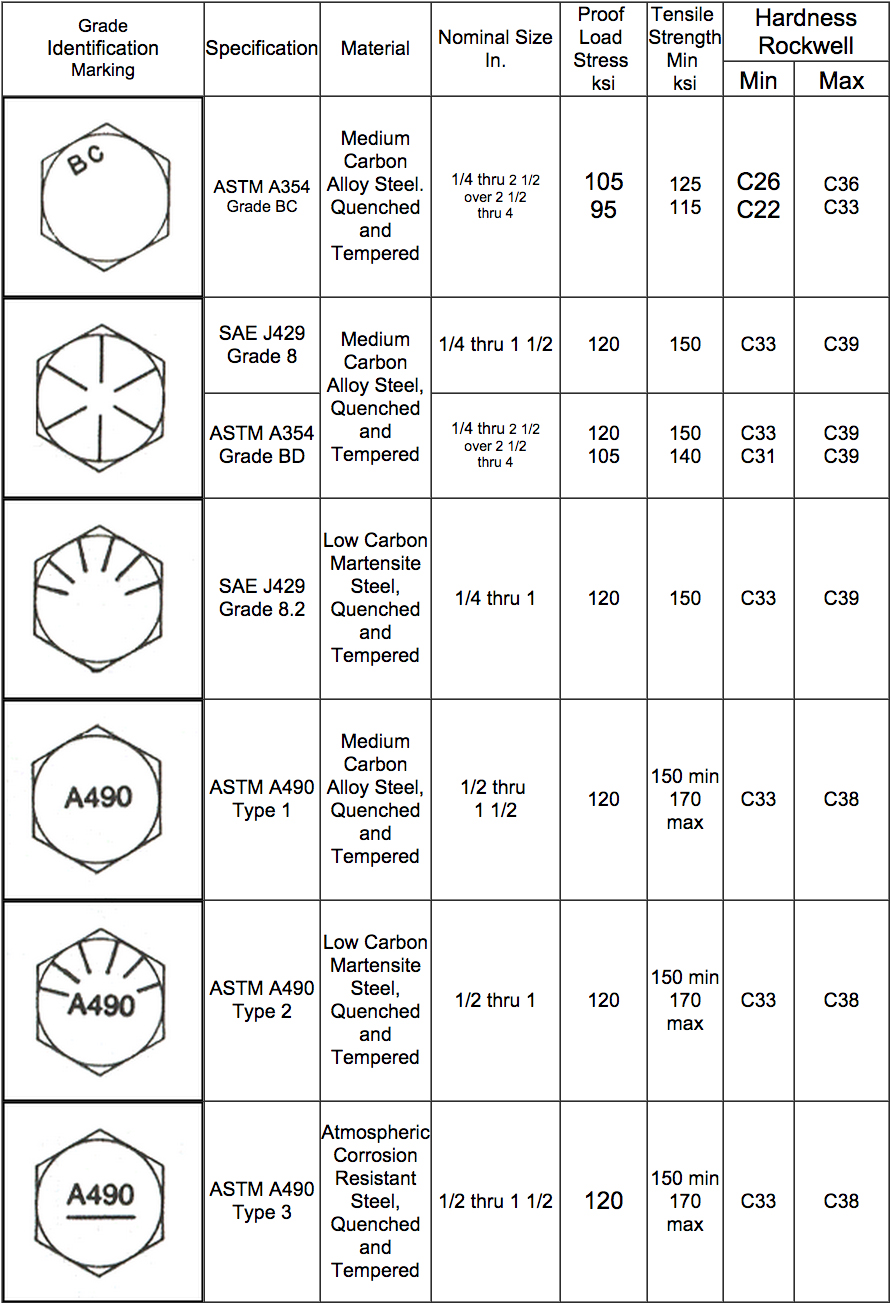

The fabric of the shoulder bolt is crucial. Widespread supplies and their properties embrace:

-

Metal (numerous grades): Gives excessive energy and sturdiness. Grade 8.8 is a standard high-strength metal.

-

Stainless Metal (numerous grades): Supplies glorious corrosion resistance. Grades like 304 and 316 are incessantly used.

-

Brass: Gives good corrosion resistance and is commonly utilized in much less demanding functions.

-

Aluminum: Light-weight and corrosion-resistant, appropriate for functions the place weight is a priority.

Past the Chart: Sensible Issues

Whereas a dimension chart gives important info, it is important to contemplate sensible elements throughout choice and software:

-

Pre-drilling: At all times pre-drill holes to the proper dimension to keep away from damaging the threads or the encircling materials.

-

Lubrication: Utilizing acceptable lubricant can cut back friction throughout set up and enhance the clamping power.

-

Torque Management: Use a torque wrench to make sure correct tightening and keep away from over-tightening, which might injury the bolt or the related elements.

-

Inspection: Commonly examine shoulder bolts for indicators of damage, injury, or corrosion. Exchange any broken bolts promptly.

Conclusion:

Metric shoulder bolt dimension charts are important instruments for engineers, technicians, and anybody working with these fasteners. Understanding the varied dimensions, tolerances, materials specs, and software issues is crucial for choosing the proper bolt and guaranteeing the protection and reliability of the assembled construction. This information gives a complete overview, enabling customers to confidently navigate the complexities of metric shoulder bolt sizing and choice. Keep in mind to at all times seek the advice of related requirements and specs for particular functions to make sure compliance and optimum efficiency. By fastidiously contemplating all these components, you’ll be able to make sure the profitable and dependable use of metric shoulder bolts in any challenge.

Closure

Thus, we hope this text has offered invaluable insights into Decoding the Metric Shoulder Bolt Measurement Chart: A Complete Information. We thanks for taking the time to learn this text. See you in our subsequent article!