Decoding the MS Hole Spherical Pipe Weight Chart: A Complete Information

Associated Articles: Decoding the MS Hole Spherical Pipe Weight Chart: A Complete Information

Introduction

On this auspicious event, we’re delighted to delve into the intriguing matter associated to Decoding the MS Hole Spherical Pipe Weight Chart: A Complete Information. Let’s weave attention-grabbing data and supply contemporary views to the readers.

Desk of Content material

Decoding the MS Hole Spherical Pipe Weight Chart: A Complete Information

Delicate metal (MS) hole spherical pipes, also called tubes, are ubiquitous in development, manufacturing, and numerous different industries. Their light-weight but sturdy nature makes them very best for a variety of functions, from scaffolding and handrails to automotive parts and furnishings. Understanding the burden of those pipes is essential for correct materials estimation, structural calculations, and value optimization. This text delves deep into MS hole spherical pipe weight charts, explaining their intricacies, influencing components, and sensible functions.

Understanding the Weight Calculation:

The burden of an MS hole spherical pipe is not merely a matter of its outer diameter. A number of components contribute to the ultimate weight, and these are meticulously accounted for in weight charts:

- Outer Diameter (OD): That is the most important diameter of the pipe, measured from the skin edge to the other outdoors edge.

- Inside Diameter (ID): Also referred to as the bore, that is the diameter of the hole area contained in the pipe.

- Wall Thickness (WT): The distinction between the outer diameter and the interior diameter divided by two. This can be a crucial issue influencing the pipe’s power and weight.

- Size: The size of the pipe, sometimes measured in meters.

- Materials Density: Delicate metal has a normal density, however slight variations can happen relying on the alloying components and manufacturing course of. Weight charts normally assume a normal density for MS.

The basic formulation used to calculate the burden of an MS hole spherical pipe is predicated on the quantity of metal and its density:

Weight = Quantity × Density

The place:

- Quantity = π/4 × (OD² – ID²) × Size (This calculates the quantity of the metal within the pipe’s cross-section, accounting for the hole core.)

- Density: Sometimes round 7850 kg/m³ for delicate metal.

Decoding the MS Hole Spherical Pipe Weight Chart:

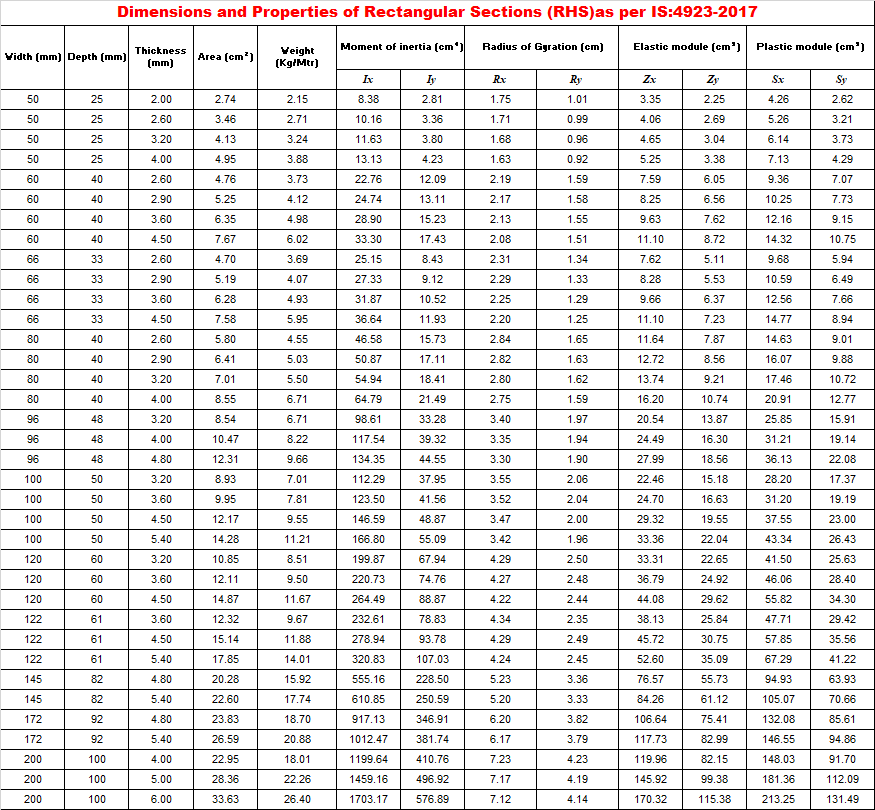

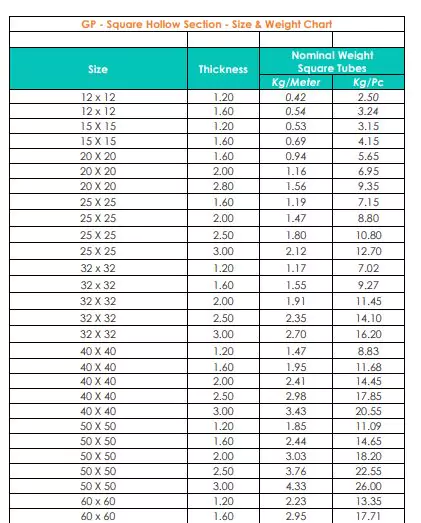

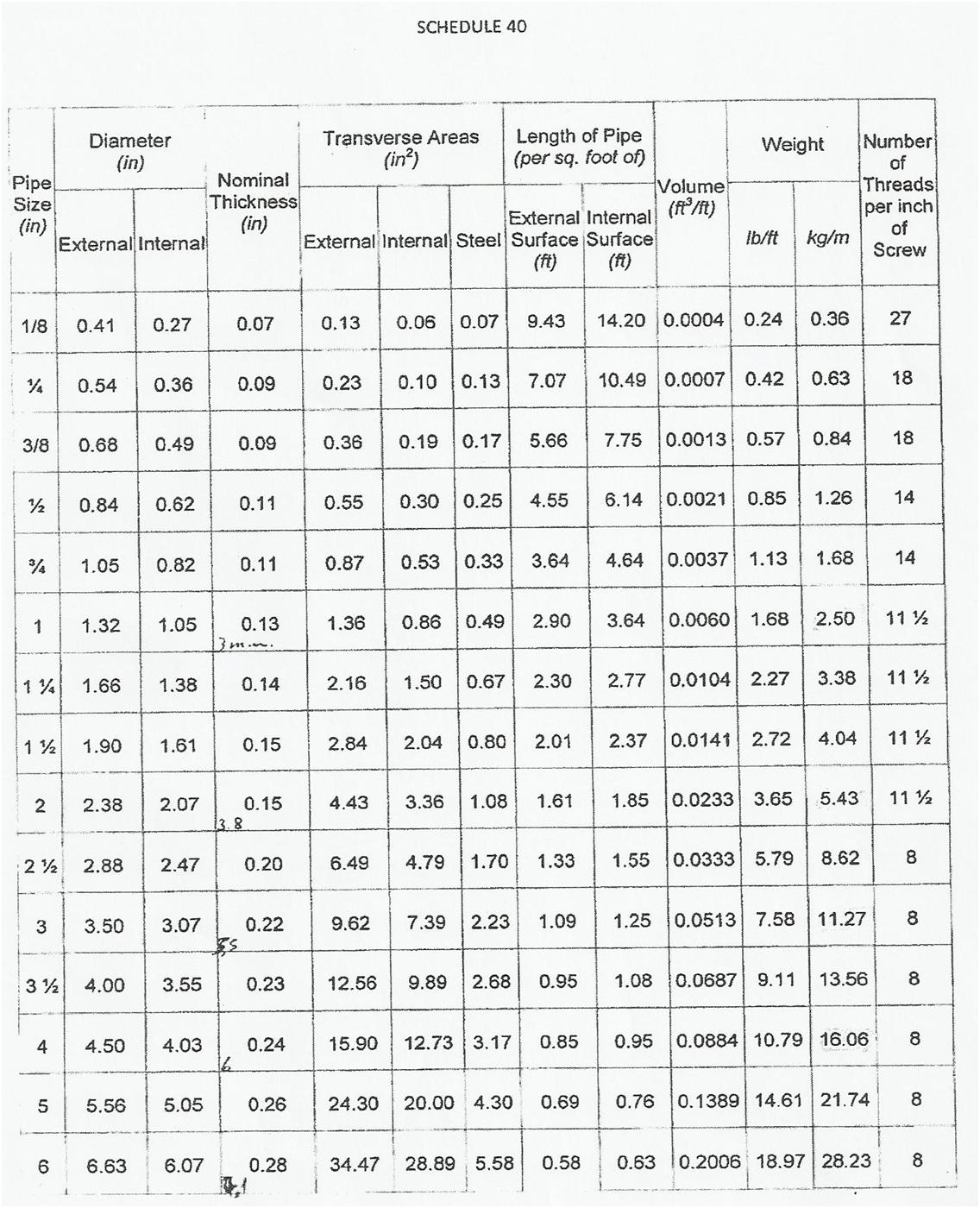

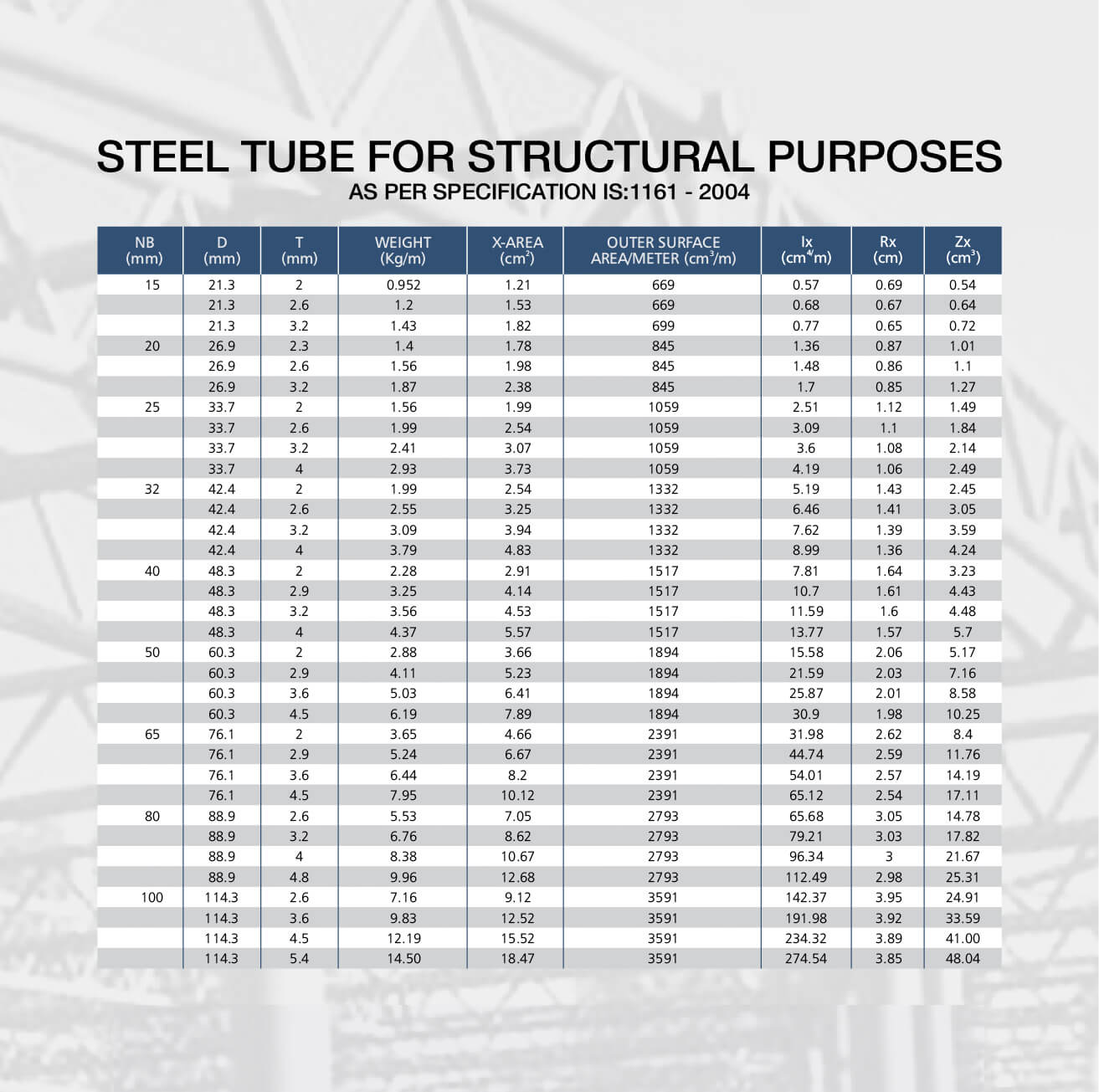

MS hole spherical pipe weight charts normally current knowledge in a tabular format. These charts sometimes arrange data primarily based on customary pipe sizes. A typical chart may embody columns for:

- Outer Diameter (OD) in mm: Itemizing numerous customary sizes out there.

- Wall Thickness (WT) in mm: Exhibiting completely different wall thicknesses for every OD.

- Weight per meter (kg/m): The calculated weight of a one-meter size of pipe with the required OD and WT.

- Weight per foot (lbs/ft): Typically included for customers working in imperial items.

Components Affecting Weight Variations:

Whereas customary weight charts present approximation, slight variations can happen attributable to:

- Manufacturing Tolerances: The precise OD, ID, and WT may deviate barely from the nominal values specified within the chart attributable to manufacturing processes.

- Materials Composition: Minor variations within the metal alloy can have an effect on the density.

- Floor End: Coatings or floor remedies can add a negligible quantity of weight.

Purposes of MS Hole Spherical Pipe Weight Charts:

Correct weight data is crucial for numerous functions:

- Structural Engineering: Engineers use weight charts to calculate the general weight of metal buildings, making certain sufficient help and basis design. That is essential for buildings, bridges, and different large-scale tasks.

- Materials Procurement: Correct weight calculations enable for exact materials ordering, minimizing waste and optimizing prices.

- Transportation and Logistics: Understanding the burden is crucial for environment friendly transportation planning, making certain automobiles are adequately loaded and transportation prices are precisely estimated.

- Price Estimation: The burden data is essential for correct venture budgeting and value management.

- Manufacturing and Fabrication: Weight knowledge is important for designing and fabricating parts that require particular weight limitations or steadiness.

- Stock Administration: Correct weight information help in sustaining environment friendly stock management and monitoring of supplies.

Utilizing the Weight Chart Successfully:

To make use of an MS hole spherical pipe weight chart successfully:

- Determine the required OD and WT: Decide the pipe dimensions wanted to your particular utility.

- Find the corresponding weight: Discover the intersection of the chosen OD and WT within the chart to search out the burden per unit size.

- Calculate the entire weight: Multiply the burden per unit size by the required whole size of the pipe.

- Account for tolerances: Keep in mind that slight variations from the chart values are doable attributable to manufacturing tolerances. Take into account including a small security margin to your calculations, particularly for crucial functions.

Past the Fundamental Chart:

Whereas customary charts present weight data for frequent pipe sizes, specialised charts or software program could also be required for much less frequent dimensions or for pipes with non-standard materials properties. Some suppliers present customized weight calculations primarily based on particular necessities.

Conclusion:

The MS hole spherical pipe weight chart is an indispensable software for anybody working with these versatile supplies. Understanding how these charts are constructed, the components that affect pipe weight, and learn how to interpret the information precisely are essential for profitable venture planning, environment friendly materials administration, and value optimization. By mastering using these charts, professionals can make sure the structural integrity and financial viability of their tasks. All the time consult with probably the most up-to-date and dependable weight charts offered by respected producers or suppliers to make sure accuracy and consistency in your calculations. Bear in mind to all the time double-check your calculations and take into account potential variations attributable to manufacturing tolerances. Correct use of those charts is paramount for profitable implementation in various functions.

Closure

Thus, we hope this text has offered priceless insights into Decoding the MS Hole Spherical Pipe Weight Chart: A Complete Information. We thanks for taking the time to learn this text. See you in our subsequent article!