Mastering Duct Design: A Complete Information to Duct Design Charts and Calculations

Associated Articles: Mastering Duct Design: A Complete Information to Duct Design Charts and Calculations

Introduction

With enthusiasm, let’s navigate by the intriguing subject associated to Mastering Duct Design: A Complete Information to Duct Design Charts and Calculations. Let’s weave fascinating data and provide contemporary views to the readers.

Desk of Content material

Mastering Duct Design: A Complete Information to Duct Design Charts and Calculations

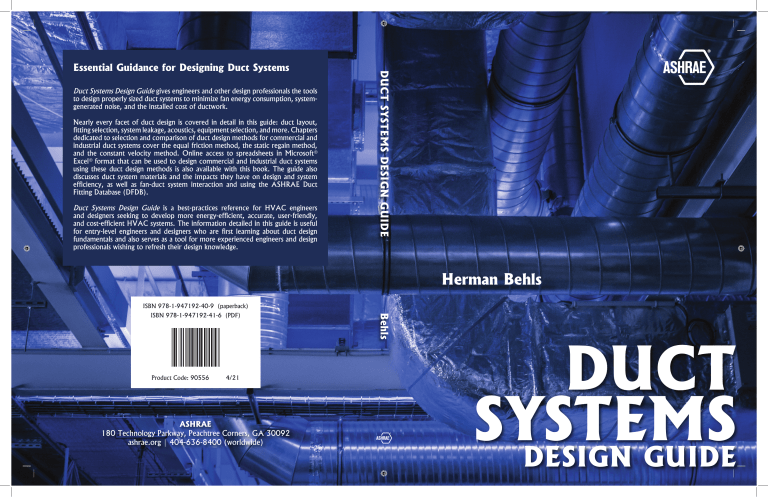

Environment friendly HVAC methods rely closely on correctly designed ductwork. A well-designed duct system ensures constant airflow all through a constructing, maximizing heating and cooling efficiency whereas minimizing power waste and noise. Central to this design course of are duct design charts, highly effective instruments that simplify the advanced calculations concerned in sizing and deciding on acceptable ductwork. This text supplies a complete overview of duct design charts, their utility, and the essential concerns for correct and efficient duct system design.

Understanding the Fundamentals: Airflow, Strain, and Friction

Earlier than diving into duct design charts, it is essential to grasp the basic rules governing airflow inside a duct system. The first elements influencing duct design are:

-

Airflow (CFM): Cubic Toes per Minute (CFM) represents the amount of air transferring by the duct per minute. That is decided by the heating or cooling load of the area being served.

-

Velocity (fpm): Air velocity (ft per minute) is the pace at which air travels by the duct. Optimizing velocity is essential; extreme velocity results in elevated noise and power loss, whereas inadequate velocity may end up in insufficient airflow. Really helpful velocity ranges differ relying on the duct sort and utility.

-

Static Strain (inches of water gauge): Static strain represents the strain distinction between the availability and return air. It overcomes friction throughout the ductwork and fittings, guaranteeing sufficient airflow to the diffusers and grilles. Larger static strain usually signifies larger power consumption.

-

Friction Loss: As air strikes by the duct, it encounters friction as a result of duct’s floor space and the air’s viscosity. This friction loss interprets to a strain drop alongside the duct’s size. Correct calculation of friction loss is paramount for correct duct sizing.

The Function of Duct Design Charts

Duct design charts are invaluable instruments that simplify the advanced calculations required to find out the suitable measurement and sort of duct for a given airflow and strain drop. These charts usually current information in tabular or graphical format, relating duct dimensions (diameter or width and peak for rectangular ducts), airflow (CFM), and friction loss (inches of water gauge per 100 ft of duct). They account for various duct supplies (galvanized metal, aluminum, fiberglass) and shapes (spherical, rectangular).

Sorts of Duct Design Charts

A number of kinds of duct design charts exist, every with its personal benefits and limitations:

-

Friction Loss Charts: These charts instantly correlate duct dimensions, airflow, and friction loss. They’re broadly used for fast estimations and preliminary design.

-

Velocity Strain Charts: These charts deal with air velocity throughout the duct, offering insights into noise ranges and potential power losses related to totally different velocities. They’re usually used at the side of friction loss charts.

-

Equal Size Charts: These charts simplify calculations for advanced duct methods by changing fittings and bends into equal lengths of straight duct, thus simplifying the general friction loss calculation.

-

Software program-Based mostly Charts and Calculators: Fashionable HVAC design usually makes use of specialised software program incorporating subtle algorithms and intensive databases for correct duct design. These applications combine varied charts and calculations, offering a complete and environment friendly design course of.

Utilizing Duct Design Charts: A Step-by-Step Strategy

The exact technique for utilizing a duct design chart varies relying on the particular chart’s format. Nevertheless, the final course of includes the next steps:

-

Decide the Required Airflow (CFM): That is normally decided primarily based on the load calculations for every room or zone within the constructing.

-

Choose the Desired Air Velocity: Select an acceptable velocity primarily based on the kind of duct, utility, and noise concerns. Decrease velocities usually result in quieter operation however may require bigger ducts.

-

Find the Related Chart: Choose the suitable chart primarily based on the duct materials and form (spherical or rectangular).

-

Discover the Intersection: Utilizing the decided CFM and desired velocity (or friction loss), find the intersection on the chart. This intersection will point out the suitable duct dimensions.

-

Verify for Strain Drop: Be sure that the entire strain drop throughout the complete duct system (together with fittings and bends) stays inside acceptable limits. Extreme strain drop can result in diminished airflow and elevated power consumption.

-

Iterative Design: The method may require iteration. If the chosen duct measurement ends in unacceptable strain drop or velocity, changes to duct measurement or velocity is likely to be vital.

Essential Issues in Duct Design

Past the direct utility of duct design charts, a number of crucial elements affect the general effectiveness and effectivity of a duct system:

-

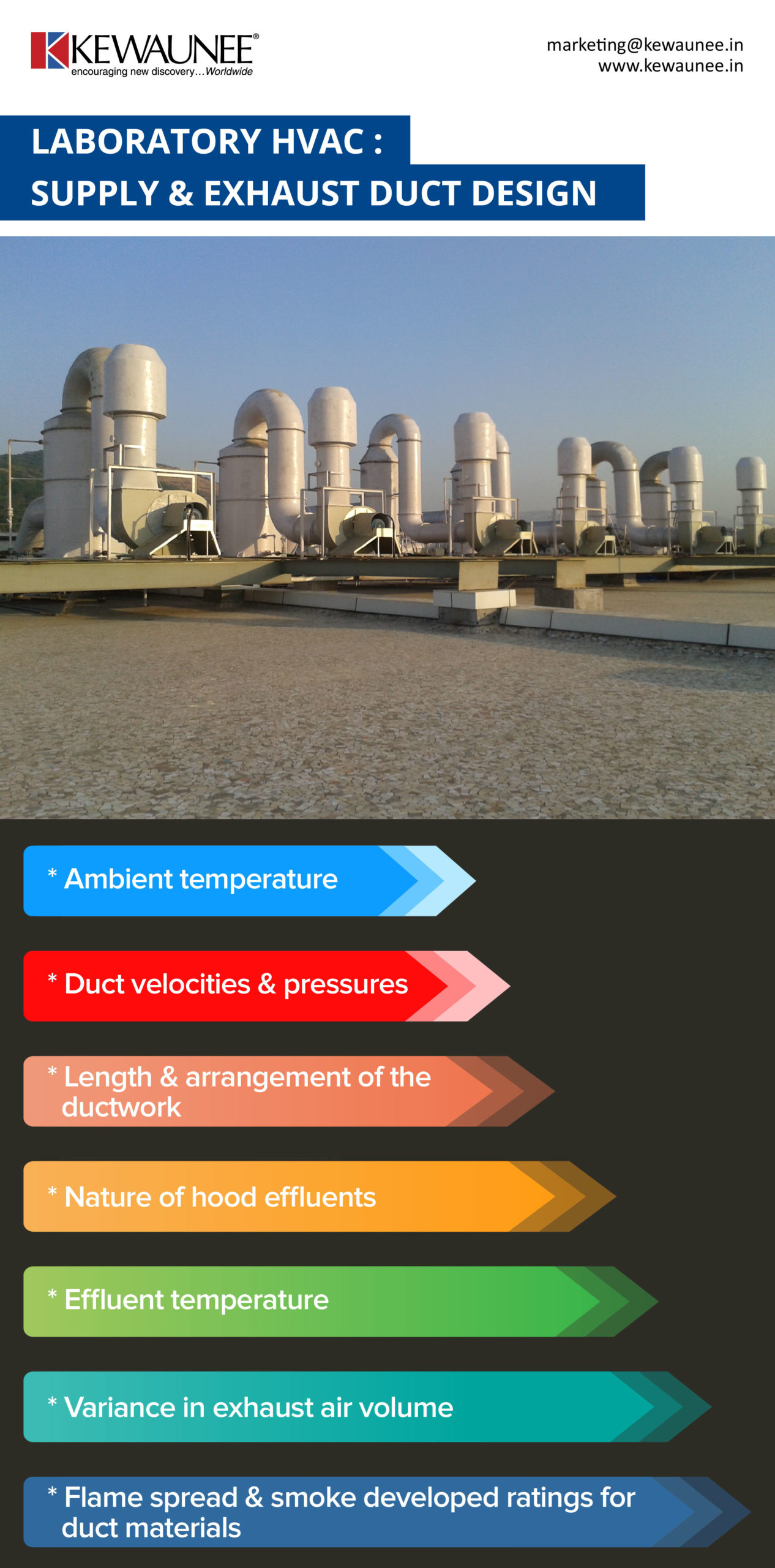

Duct Materials: The selection of duct materials impacts friction loss, sturdiness, and value. Galvanized metal is a typical selection for its energy and sturdiness, whereas versatile ductwork gives flexibility however might have larger friction loss.

-

Duct Form: Spherical ducts usually provide decrease friction loss in comparison with rectangular ducts for a similar airflow. Nevertheless, rectangular ducts are sometimes most popular for area constraints in ceilings and partitions.

-

Fittings and Bends: Fittings (elbows, transitions, dampers) introduce further friction loss. Equal size charts assist account for this added resistance. Minimizing the variety of fittings and utilizing clean bends can enhance effectivity.

-

Insulation: Insulating ducts reduces warmth switch, bettering power effectivity and stopping condensation. That is particularly essential in climates with vital temperature variations.

-

Leakage: Air leakage from the duct system reduces effectivity and may impression indoor air high quality. Correct sealing and connections are essential to reduce leakage.

-

Static Strain Issues: Sustaining acceptable static strain all through the system ensures constant airflow to all retailers. An excessive amount of strain can result in extreme power consumption, whereas inadequate strain ends in poor efficiency.

-

System Balancing: After set up, the system must be balanced to make sure even airflow to all zones. This may contain adjusting dampers to fine-tune airflow distribution.

Superior Duct Design Methods

Past primary chart utilization, superior methods improve duct design accuracy and effectivity:

-

Computational Fluid Dynamics (CFD): CFD simulations present extremely correct airflow modeling, contemplating advanced geometries and stream patterns. That is significantly helpful for big or advanced methods.

-

Equal Friction Technique: This technique ensures uniform strain drop per unit size all through the duct system, optimizing airflow distribution.

-

Fixed Velocity Technique: This technique maintains a continuing air velocity all through the duct system, simplifying design and decreasing noise.

Conclusion

Duct design charts are important instruments for HVAC professionals, enabling environment friendly and efficient duct system design. Nevertheless, proficient use requires a radical understanding of airflow rules, strain drop calculations, and the varied elements influencing duct efficiency. Whereas charts simplify calculations, a holistic method contemplating materials choice, becoming optimization, insulation, and leakage management is essential for making a high-performing, energy-efficient, and quiet HVAC system. Fashionable software program instruments additional improve the design course of, permitting for classy modeling and evaluation, resulting in optimized ductwork designs that meet particular constructing necessities and maximize occupant consolation. By mastering the rules outlined on this article and leveraging obtainable instruments, HVAC professionals can create duct methods that contribute considerably to constructing effectivity and occupant well-being.

Closure

Thus, we hope this text has supplied worthwhile insights into Mastering Duct Design: A Complete Information to Duct Design Charts and Calculations. We thanks for taking the time to learn this text. See you in our subsequent article!