np chart vs c chart

Associated Articles: np chart vs c chart

Introduction

With nice pleasure, we are going to discover the intriguing subject associated to np chart vs c chart. Let’s weave fascinating data and provide recent views to the readers.

Desk of Content material

NP Chart vs. C Chart: Selecting the Proper Management Chart for Your Knowledge

Management charts are indispensable instruments in statistical course of management (SPC), offering a visible illustration of course of stability and serving to establish potential sources of variation. Two generally used management charts for attribute information (information that represents the presence or absence of a attribute) are the np chart and the c chart. Whereas each intention to observe defects or nonconformities, they differ considerably of their utility and the kind of information they require. Selecting the best chart is essential for correct course of monitoring and efficient high quality enchancment. This text delves into the nuances of np charts and c charts, highlighting their variations, functions, and issues for efficient implementation.

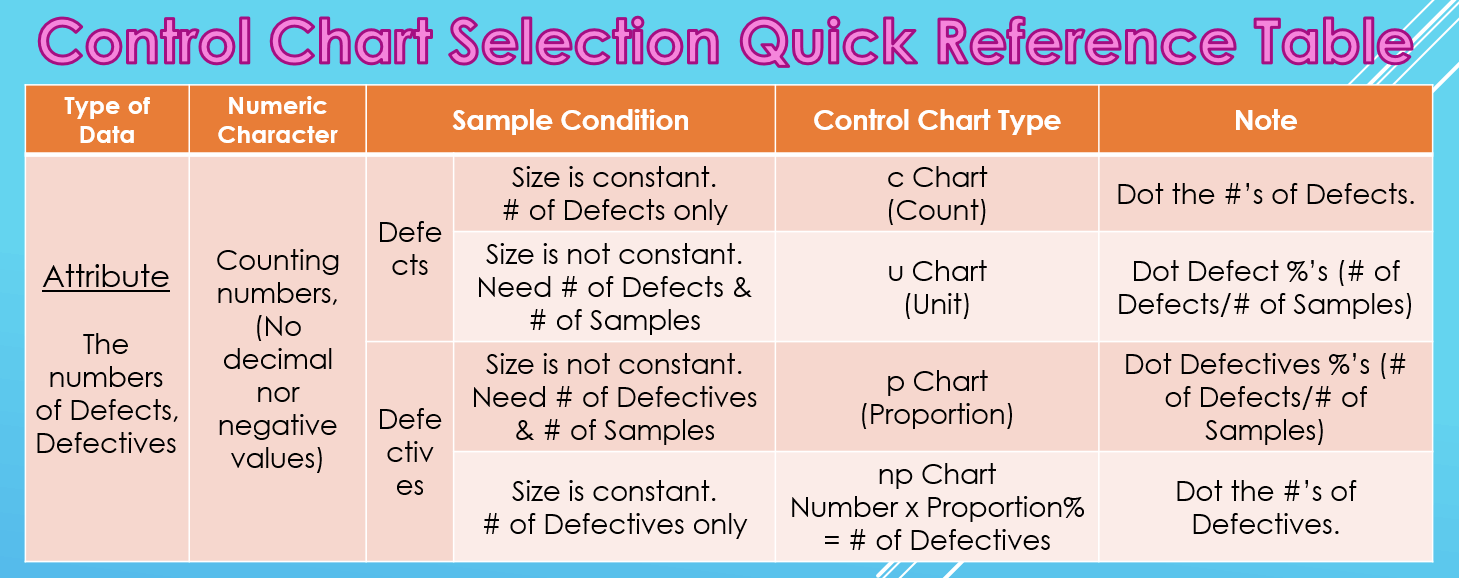

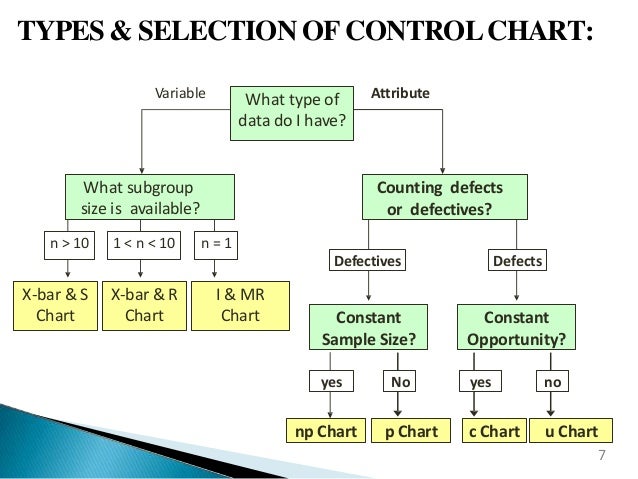

Understanding Attribute Knowledge and Management Charts

Earlier than diving into the specifics of np and c charts, it is important to know the context of attribute information. In contrast to variable information (e.g., weight, size, temperature), attribute information focuses on the presence or absence of a attribute. This attribute generally is a defect, a nonconformity, or another attribute of curiosity. For example, in a producing course of, the attribute could possibly be the presence of a scratch on a product, whereas in a service setting, it could possibly be the variety of buyer complaints.

Management charts for attribute information assist monitor the proportion or rely of defects or nonconformities over time. They visually show the information, permitting for the identification of patterns that point out course of instability or the presence of particular trigger variation (versus widespread trigger variation inherent within the course of). This permits for well timed interventions to stop defects and enhance course of effectivity.

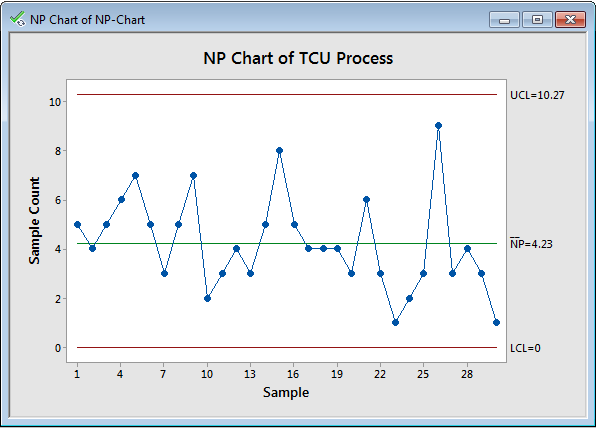

The NP Chart: Monitoring the Proportion of Nonconforming Items

The np chart is used to observe the variety of nonconforming items in a fixed pattern dimension. Which means the variety of gadgets inspected (the pattern dimension, ‘n’) stays the identical for every subgroup or pattern taken. The ‘p’ in ‘np’ represents the proportion of nonconforming items. The chart plots the variety of nonconforming items (np) for every subgroup.

Key Traits of the NP Chart:

- Fixed Pattern Dimension: Essentially the most essential side of an np chart is the constant pattern dimension. Variations in pattern dimension will invalidate the chart’s calculations and interpretations.

- Deal with Proportion: Whereas plotting the variety of nonconformities, the underlying metric is the proportion of nonconformities inside the pattern. This permits for comparisons throughout totally different pattern sizes (although the pattern dimension should stay fixed inside the chart).

- Appropriate for Massive Pattern Sizes: The np chart is mostly simpler when the pattern dimension (n) is comparatively giant, making certain a steady estimate of the proportion of nonconformities.

- Management Limits Calculation: The management limits for an np chart are calculated utilizing the typical variety of nonconforming items (np̄) and the usual deviation of the variety of nonconforming items (√(np̄(1-p̄))). These calculations make the most of the historic information to determine the baseline course of efficiency.

Instance: A producing course of produces 100 items per hour. Each hour, a pattern of 20 items is inspected, and the variety of faulty items is recorded. An np chart can be used to observe the variety of faulty items per hour.

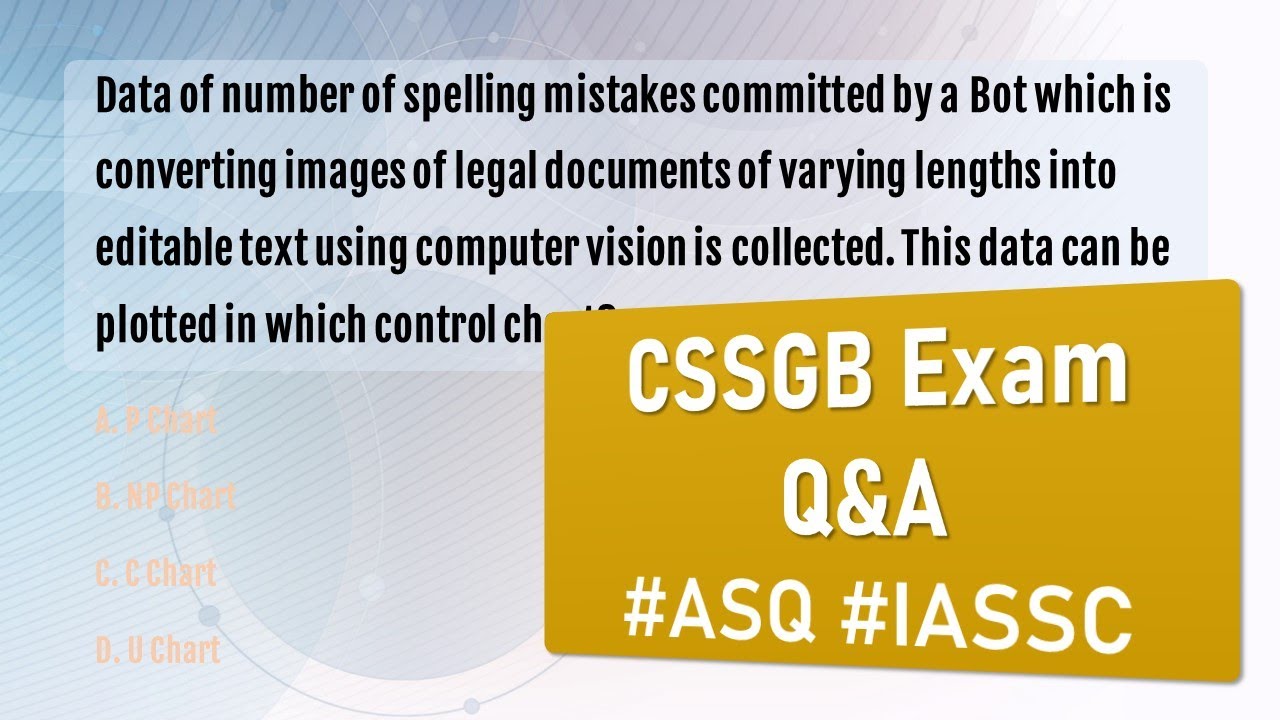

The C Chart: Monitoring the Variety of Nonconformities per Unit

The c chart, in contrast to the np chart, displays the variety of nonconformities per unit (or per pattern) whatever the pattern dimension. Which means the pattern dimension can fluctuate from subgroup to subgroup, however the focus is on the overall variety of nonconformities noticed in every unit or pattern. The ‘c’ represents the typical variety of nonconformities.

Key Traits of the C Chart:

- Variable Pattern Dimension: The first distinction from the np chart is the allowance for variable pattern sizes. The variety of nonconformities is tracked whatever the variety of items inspected.

- Deal with Nonconformities per Unit: The chart immediately plots the variety of nonconformities present in every unit or pattern, making it appropriate for conditions the place a number of defects can happen on a single unit.

- Appropriate for Conditions with A number of Defects: The c chart is good for conditions the place every unit or pattern can have a number of defects, such because the variety of scratches on a automotive panel or the variety of defects in a roll of cloth.

- Management Limits Calculation: The management limits for a c chart are calculated utilizing the typical variety of nonconformities (c̄) and the usual deviation of the variety of nonconformities (√c̄).

Instance: A textile producer inspects rolls of cloth and information the variety of defects present in every roll. The variety of defects per roll can fluctuate, making a c chart the suitable alternative. One other instance could possibly be the variety of errors present in a software program program, the place a single program may comprise a number of errors.

Selecting Between NP Chart and C Chart: A Comparative Evaluation

The selection between an np chart and a c chart is determined by the character of the information and the precise utility. Here is a desk summarizing the important thing variations to assist in decision-making:

| Characteristic | NP Chart | C Chart |

|---|---|---|

| Pattern Dimension | Fixed | Variable |

| Metric | Variety of nonconforming items (np) | Variety of nonconformities (c) |

| Focus | Proportion of nonconforming items | Variety of nonconformities per unit/pattern |

| Defects per Unit | One defect per unit is assumed | A number of defects per unit are allowed |

| Greatest Suited For | Monitoring a constant pattern dimension | Monitoring variable pattern sizes or a number of defects per unit |

Sensible Issues and Implementation

Whatever the chosen chart, a number of sensible issues should be addressed for efficient implementation:

- Knowledge Assortment: Correct and constant information assortment is paramount. Set up clear definitions of defects and nonconformities to keep away from ambiguity.

- Subgroup Dimension: Choosing an applicable subgroup dimension is essential. Bigger subgroups present extra exact estimates however might masks delicate shifts within the course of.

- Historic Knowledge: Enough historic information is required to determine baseline management limits. A minimal of 20-25 subgroups is mostly really helpful.

- Software program Instruments: Statistical software program packages (e.g., Minitab, JMP) simplify the method of making and decoding management charts.

- Interpretation: Understanding the that means of factors outdoors the management limits is essential. Examine the causes of out-of-control factors to establish and remove particular trigger variation.

Conclusion

Each np charts and c charts are invaluable instruments for monitoring attribute information in SPC. The selection between them hinges on whether or not the pattern dimension stays fixed (np chart) or varies (c chart) and whether or not a number of defects can happen inside a single unit (c chart). Cautious consideration of those elements, coupled with correct information assortment and interpretation, ensures the efficient use of those charts for course of enchancment and high quality management. By understanding the strengths and limitations of every chart, practitioners could make knowledgeable selections to pick probably the most applicable device for his or her particular wants, resulting in simpler course of monitoring and enhanced high quality outcomes. Keep in mind that constant utility and interpretation of those charts are key to realizing their full potential in bettering course of stability and decreasing defects.

Closure

Thus, we hope this text has supplied invaluable insights into np chart vs c chart. We hope you discover this text informative and helpful. See you in our subsequent article!