Understanding the X-Bar Chart: A Deep Dive into Course of Management and Monitoring

Associated Articles: Understanding the X-Bar Chart: A Deep Dive into Course of Management and Monitoring

Introduction

On this auspicious event, we’re delighted to delve into the intriguing subject associated to Understanding the X-Bar Chart: A Deep Dive into Course of Management and Monitoring. Let’s weave attention-grabbing info and provide contemporary views to the readers.

Desk of Content material

Understanding the X-Bar Chart: A Deep Dive into Course of Management and Monitoring

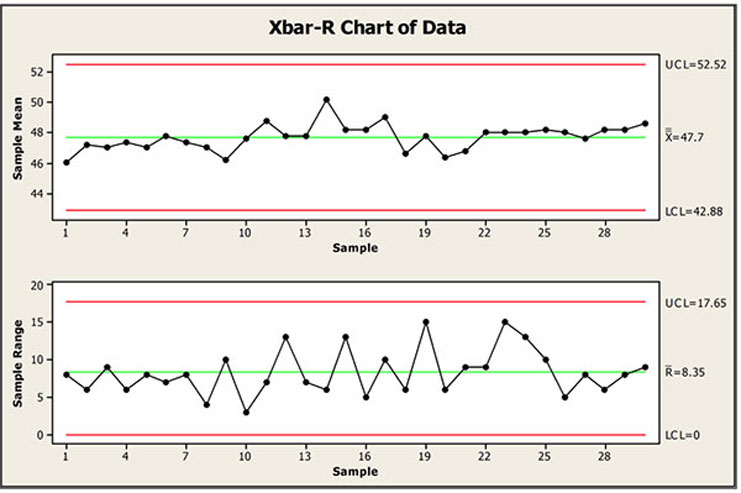

The X-bar chart, often known as the X-bar and R chart or the typical and vary chart, is a strong statistical course of management (SPC) instrument used to watch the central tendency and variability of a course of over time. It is a essential element of high quality management methodologies, enabling producers, service suppliers, and different organizations to establish shifts in course of efficiency and take corrective actions earlier than defects accumulate. This text offers a complete understanding of the X-bar chart, its development, interpretation, and purposes.

What’s an X-Bar Chart?

The X-bar chart is a graphical illustration of the typical (imply) of subgroups of information collected from a course of. Every level on the chart represents the typical of a pattern taken at a particular time or location. The chart visually shows the method common over time, permitting for the detection of tendencies, shifts, or uncommon patterns that point out potential issues. It is usually used along with a spread chart (R-chart), which screens the variability inside every subgroup. The mixture of those two charts offers a whole image of course of stability.

The Parts of an X-Bar Chart:

An X-bar chart consists of a number of key elements:

-

The Middle Line (CL): This line represents the general common of all of the subgroup averages. It is calculated by averaging all of the subgroup means. It serves as a benchmark in opposition to which the method efficiency is evaluated.

-

Higher Management Restrict (UCL): This line represents the higher boundary past which the method common is taken into account statistically unlikely to happen if the method is in management. Factors falling above the UCL recommend a possible enhance within the common course of output, indicating a attainable downside.

-

Decrease Management Restrict (LCL): This line represents the decrease boundary beneath which the method common is taken into account statistically unlikely to happen if the method is in management. Factors falling beneath the LCL recommend a possible lower within the common course of output, indicating a attainable downside.

-

Subgroup Averages (X-bar): These are the person factors plotted on the chart, every representing the typical of a subgroup of information collected at a particular time.

-

Time (or Pattern Quantity): The horizontal axis of the chart represents the time or pattern quantity at which every subgroup was collected. This enables for the visualization of tendencies and adjustments within the course of common over time.

Establishing an X-Bar Chart:

Establishing an X-bar chart includes a number of steps:

-

Outline the Course of and Subgroups: Clearly outline the method to be monitored and decide the suitable subgroup dimension. The subgroup dimension must be chosen fastidiously, balancing the necessity for adequate knowledge to estimate the method variability with the practicality of information assortment. Frequent subgroup sizes vary from 4 to 10 observations.

-

Accumulate Information: Accumulate knowledge from the method in subgroups. Make sure that the info is collected persistently and precisely. The info ought to characterize a consultant pattern of the method output.

-

Calculate Subgroup Averages (X-bar): Calculate the typical of every subgroup.

-

Calculate the Total Common (X-double bar): Calculate the typical of all of the subgroup averages. This turns into the middle line (CL) of the X-bar chart.

-

Calculate the Common Vary (R-bar): Calculate the vary (the distinction between the biggest and smallest values) for every subgroup. Then, calculate the typical of those ranges. That is essential for figuring out the management limits.

-

Calculate the Management Limits: The management limits are calculated utilizing statistical formulation that incorporate the typical vary (R-bar). The commonest formulation are primarily based on the idea of usually distributed knowledge. These formulation make the most of management chart constants (A2, D3, D4) that are available in statistical tables or software program packages. The formulation are:

- *UCL = X-double bar + A2 R-bar**

- *LCL = X-double bar – A2 R-bar**

-

Plot the Information: Plot the subgroup averages (X-bar) on the chart, with the time or pattern quantity on the horizontal axis. Draw the middle line and management limits.

Decoding an X-Bar Chart:

Decoding an X-bar chart includes figuring out patterns and deviations from the established management limits. A course of is taken into account "in management" if all factors fall throughout the management limits and there aren’t any discernible patterns. Nevertheless, a number of eventualities point out potential out-of-control conditions:

-

Factors exterior the management limits: Any level falling above the UCL or beneath the LCL strongly suggests a big shift within the course of common, indicating a possible downside that requires investigation and corrective motion.

-

Developments: A constant upward or downward pattern within the knowledge factors suggests a gradual shift within the course of common. This might point out a sluggish deterioration of the method or a gradual change within the course of inputs.

-

Stratification: Clustering of information factors round particular values signifies potential issues associated to the method’s subgroups or sampling methodology.

-

Cycles or Oscillations: Recurring patterns recommend periodic variations within the course of, presumably on account of exterior components or machine cycles.

-

Runs: A sequence of consecutive factors above or beneath the middle line could point out a scientific shift within the course of, even when the person factors are throughout the management limits.

Purposes of X-Bar Charts:

X-bar charts have wide-ranging purposes throughout numerous industries and processes, together with:

-

Manufacturing: Monitoring dimensions, weights, and different traits of manufactured merchandise.

-

Healthcare: Monitoring affected person very important indicators, treatment dosages, and different medical parameters.

-

Service Industries: Monitoring buyer satisfaction scores, name dealing with occasions, and different service metrics.

-

Finance: Monitoring monetary transactions, funding returns, and different monetary indicators.

-

Analysis and Growth: Monitoring experimental outcomes and course of variables throughout analysis initiatives.

Benefits of Utilizing X-Bar Charts:

-

Early Downside Detection: X-bar charts present early warning indicators of potential issues, permitting for well timed intervention and prevention of defects.

-

Course of Enchancment: By figuring out sources of variation and addressing them, X-bar charts contribute to steady course of enchancment.

-

Lowered Prices: Stopping defects via proactive monitoring reduces waste, rework, and related prices.

-

Improved High quality: By sustaining course of stability, X-bar charts contribute to improved services or products high quality.

-

Information-Pushed Determination Making: X-bar charts present goal knowledge for knowledgeable decision-making relating to course of changes and enhancements.

Limitations of X-Bar Charts:

-

Assumption of Normality: The usual management restrict formulation assume that the info is often distributed. If the info is just not usually distributed, different strategies could also be wanted.

-

Subgroup Dimension: The selection of subgroup dimension can affect the sensitivity of the chart. Too small a subgroup dimension could masks variability, whereas too massive a dimension could also be impractical.

-

Information Assortment: Correct and constant knowledge assortment is crucial for the reliability of the chart. Inaccurate or incomplete knowledge can result in deceptive interpretations.

-

Over-reliance on Management Limits: Management limits shouldn’t be the only foundation for course of choices. Different components, equivalent to course of data and engineering judgment, must also be thought-about.

Conclusion:

The X-bar chart is a elementary instrument in statistical course of management, providing a strong methodology for monitoring course of efficiency and figuring out potential issues. By understanding its development, interpretation, and limitations, organizations can leverage this instrument to enhance high quality, cut back prices, and make data-driven choices to optimize their processes. Nevertheless, it is essential to do not forget that the X-bar chart is simplest when used along with different SPC instruments and a complete understanding of the method being monitored. The mixture of the X-bar chart with the R-chart offers a sturdy and complete method to course of monitoring and management, making certain the constant supply of high-quality services.

Closure

Thus, we hope this text has offered useful insights into Understanding the X-Bar Chart: A Deep Dive into Course of Management and Monitoring. We respect your consideration to our article. See you in our subsequent article!